Food Vibratory Conveying Systems

Packet Blowing Systems

Packet Blowing Systems are an effective way of transferring packets of product.

Features

- Simple and effective way of transferring packets of product

- Gentle product handling

- Safe by design

At KMG, we offer Packet Blowing Systems that have been engineered to meet the specific needs of the snack manufacturing industry.

KMG Packet Blowing Systems offer a simple and effective method for transferring packets of products. Our systems offer a seamless transition from the production line to packaging, ensuring that your products are handled with care and precision.

One of the standout features of KMG Packet Blowing Systems is their ability to handle products gently. Snack manufacturers understand the importance of preserving the integrity of their products, and our systems have been designed with this in mind. Large-radius ducting is utilised to transfer packets of finished products in a manner that guarantees minimal damage.

With KMG Packet Blowing Systems, you can trust that your products will reach the packaging stage in good condition, maintaining their quality and appearance.

See where else we use the Packet Blowing Systems Machine

Food Vibratory Conveying Systems with the Packet Blowing Systems

Big Bag/Multi Pack Handling

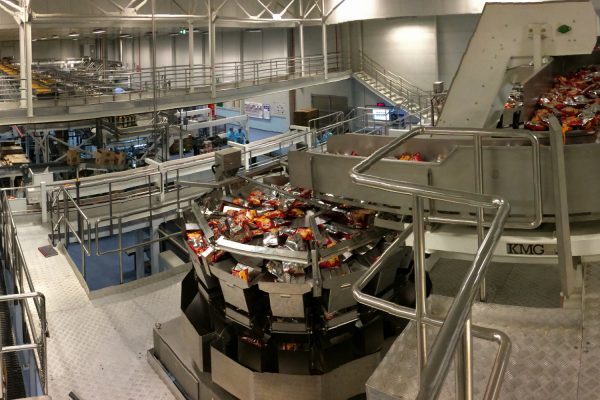

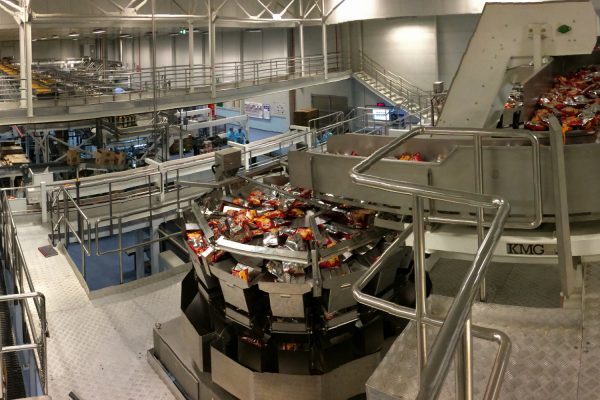

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling

Big Bag/Multi Pack Handling

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling