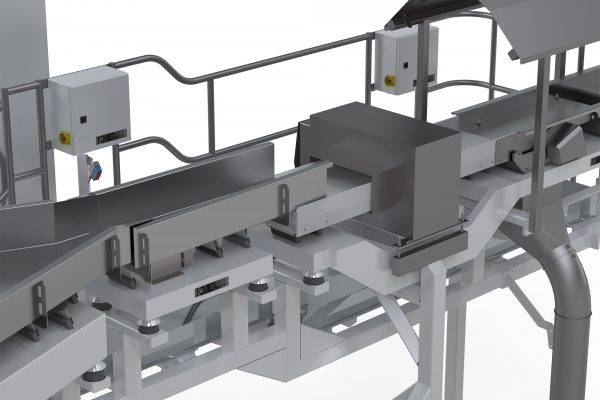

The KMG liquid spray unit is designed to be used in conjunction with the patented KMG FlowWeigher. The FlowWeigher is a special type of vibratory conveyor which enables accurate inline process weighing to ensure that exactly the right amount of liquid and seasoning is applied to the base product.

No compressed air = no oil mist

The KMG Liquid Spray unit is designed to work by producing a fan shaped spray of oil droplets and not an oil mist.

The problems with oil mist

Oil mist is a hazard to human health and can increase susceptibility to several types of cancer as well as causing other health problems such as extrinsic allergic alveolitis (also known as Hypersensitivity Pneumonitis), contact dermatitis, asthma, bronchitis and lung fibrosis to name but a few.

Oil mist particles which are larger than 3.5 microns in size are separated in the nose and throat, whilst particles smaller than 1 micron are absorbed into the bloodstream. Particles between these sizes are retained by the throat, bronchial tubes and lungs, causing a variety of occupational diseases. To put this into perspective, the diameter of an average human hair is between 10 and 50 microns.

In the UK, COSHH (Control of Substances Hazardous to Health) Regulations 2002 require employers to reduce exposure to oil mist particles to ‘as low as reasonably practicable’ – ALARP. In the majority of cases this means using an oil mist extraction system as a key control measure.

Oil mist is also a fire risk and is flammable if exposed to a source of ignition. If your process creates oil mist then you will need to invest in oil mist filters which remove this risk by capturing and containing the oil within the filter before returning clean air to your production.

Oil mist escaping from your process can also settle on floors and other surfaces and can cause slips and falls if droplets are allowed to build up on surfaces where workers walk. Accumulation of oil mist on sensitive electronic apparatus can also cause equipment to fail, interrupting production and resulting in costly downtime.

The KMG liquid spray unit avoids all these problems by operating without compressed air. Instead, the oil is pressurised and then modulated at the nozzle, producing a controlled fan shaped spray of oil droplets.