- Prevents Accidental Filling: Smart seasoning validation systems are engineered to prevent operators from mistakenly filling a seasoning hopper with the wrong seasoning. By implementing secure measures, such as barcode scanning technology, operators can ensure that only the intended seasoning is used, significantly reducing the risk of allergen contamination.

- Reduced Allergen/Cross Contamination: With the ability to validate the seasoning being used, smart seasoning validation systems effectively minimise the possibility of allergen cross-contamination. By ensuring that the correct seasoning is added, manufacturers can maintain strict control over allergen containment, safeguarding the well-being of consumers with allergies.

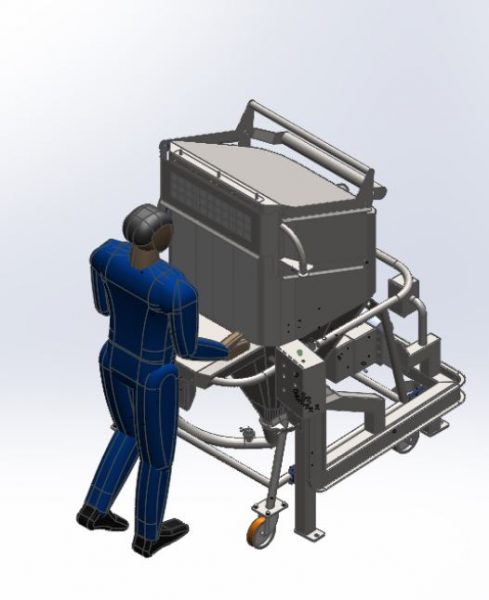

- Balanced Door Design: The smart seasoning validation system features a balanced door that requires minimal energy to open and close. This design ensures ease of use for operators, reducing physical strain during the seasoning filling process. The ergonomic door handle further enhances convenience and operator comfort.

- Barcode Scanner Dock: Equipped with a barcode scanner dock, the smart seasoning validation system streamlines the validation process. Operators can effortlessly scan the barcode on the seasoning bag, instantly verifying if it matches the recipe stored in the SCADA (Supervisory Control and Data Acquisition) system. This efficient validation mechanism helps maintain accuracy and precision in seasoning applications.

- Designed to integrate seamlessly with the KMG Vacuum Lift System, KMG Loss in Weight and KMG Powder dosing unit to produce world class seasoning accuracy for your chips, bakes, fries, cereals and other snacks.

How does Smart Seasoning Validation work?

At the core of the smart seasoning validation system is a bulk fill hopper, which is used to empty bags of seasoning. The front door of the hopper is electromagnetically locked and linked to a barcode scanner. When an operator intends to fill the hopper, they place the seasoning bag on the designated shelf and scan the barcode. If the barcode matches the recipe stored in the SCADA system, the lock disengages, allowing the operator to open the hopper and fill it with the designated seasoning. In order to maintain the integrity of the system and minimise risks, the smart seasoning validation system is designed to respond to anomalies. If the door is forced open or left open for an extended period beyond a pre-set time, the seasoning system automatically stops, preventing any potential unauthorised access or contamination.

By integrating smart seasoning validation into the production process, manufacturers can enhance safety, quality, and allergen control. The system’s ability to validate the seasoning being used ensures that only the correct ingredients are applied, reducing the risk of allergen cross-contamination, and providing consumers with peace of mind. Smart seasoning validation systems offer a robust solution to mitigate the risks associated with allergen cross-contamination in seasoning systems.

With features such as prevention of accidental filling, reduced allergen/cross-contamination, a balanced door design, and a barcode scanner dock, these systems empower professionals in the food industry to maintain strict allergen control measures. By implementing smart seasoning validation, manufacturers can uphold product integrity, protect consumer health, and enhance their reputation for producing safe and high-quality food products.