Global leader in the design and manufacture of food processing and packaging technology

Advanced Seasoning and Food Conveying Systems

KMG is the global leader in the design and manufacture of conveying and seasoning systems for the food industry. We have 50 years of experience and the best engineers in the industry.

We combine innovation and specialist knowledge to ensure that we provide the cleanest, safest, most reliable systems that combine high accuracy and gentle product handling with flexibility.

World Class

Seasoning and Conveying Systems

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system for snack manufacturers. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

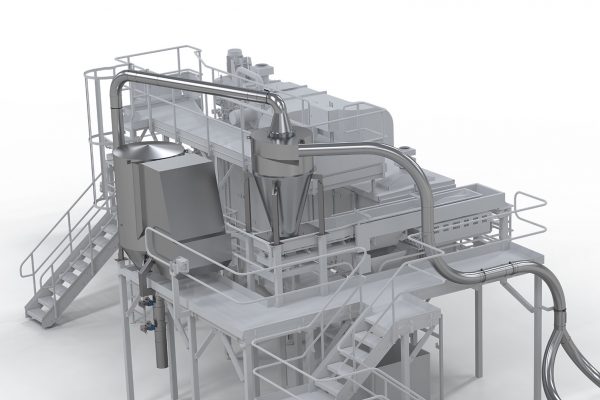

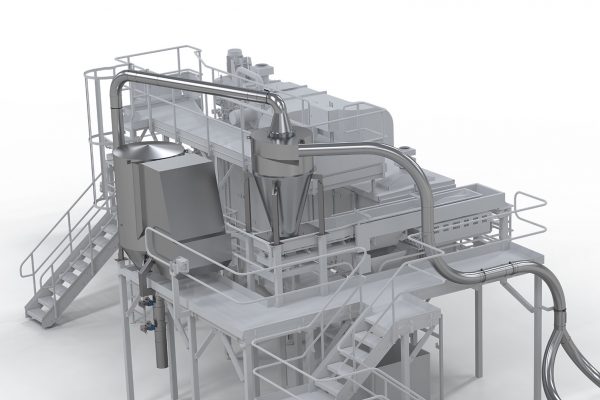

Kitchen Dry Seasoning

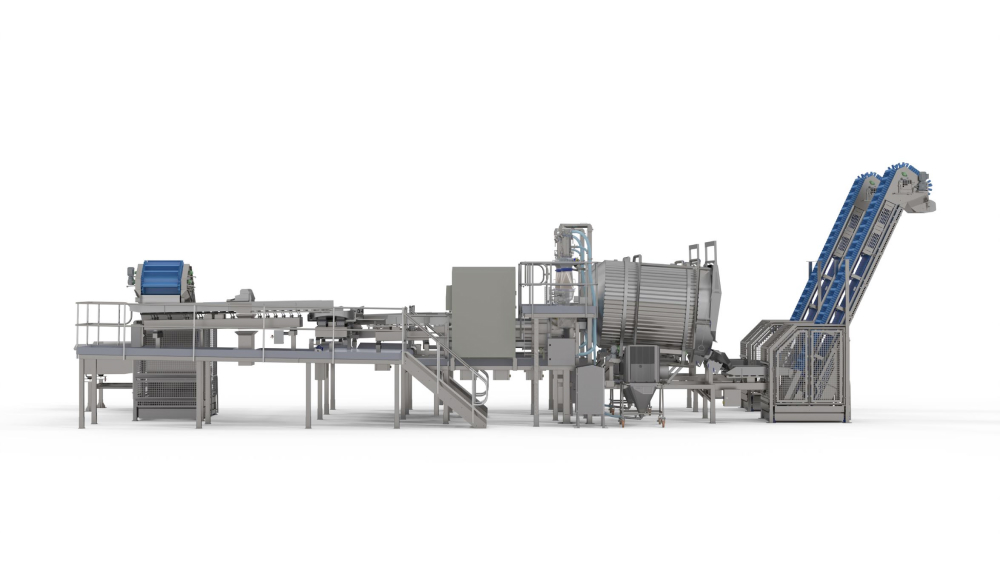

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

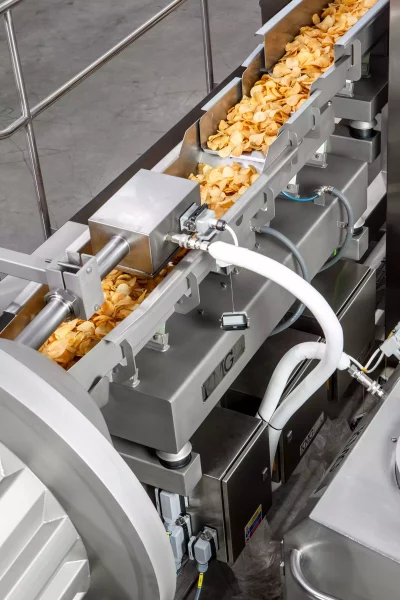

On Machine Seasoning System

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning System

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Product Blending

Food Vibratory Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Food Vibratory Conveying Systems

Elevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor Systems

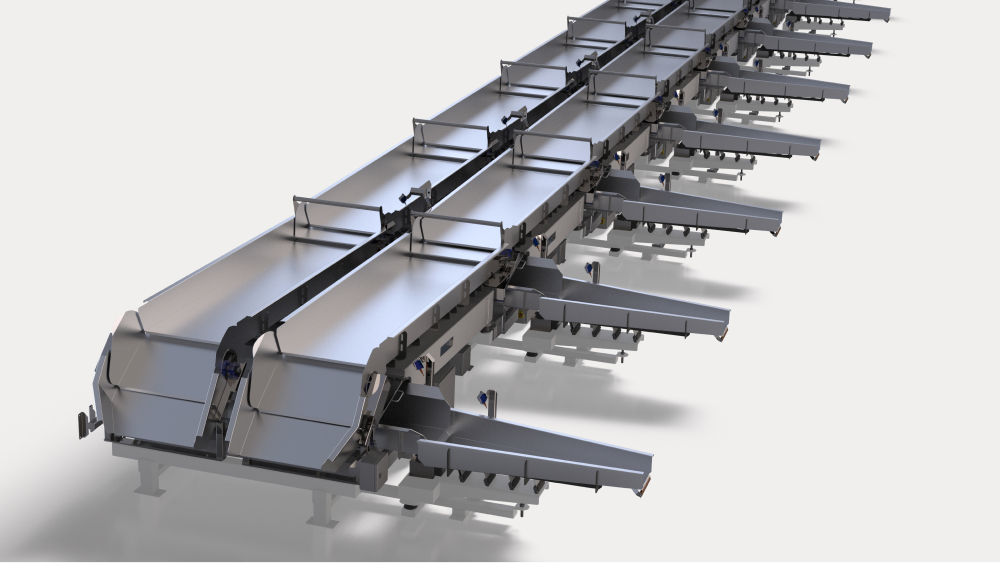

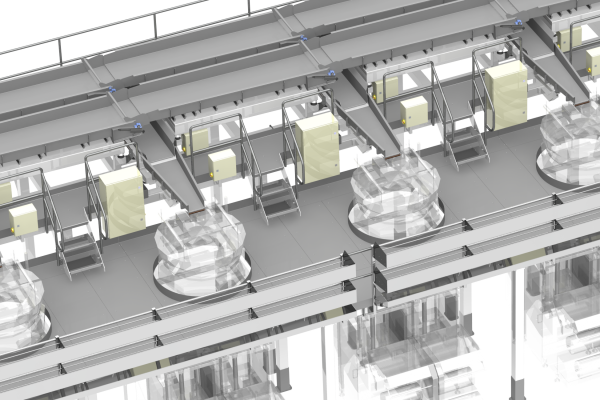

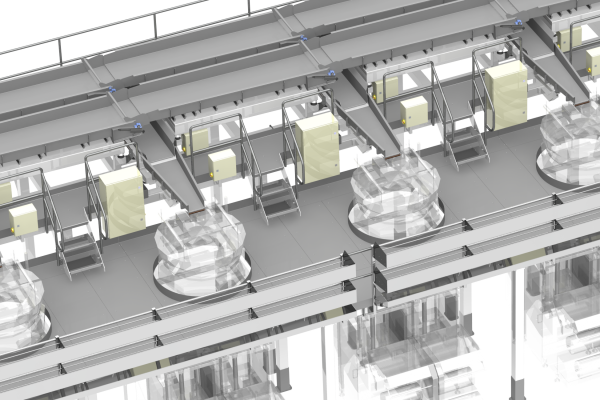

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

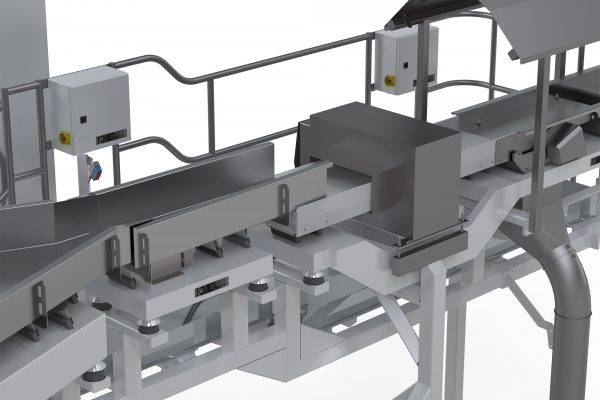

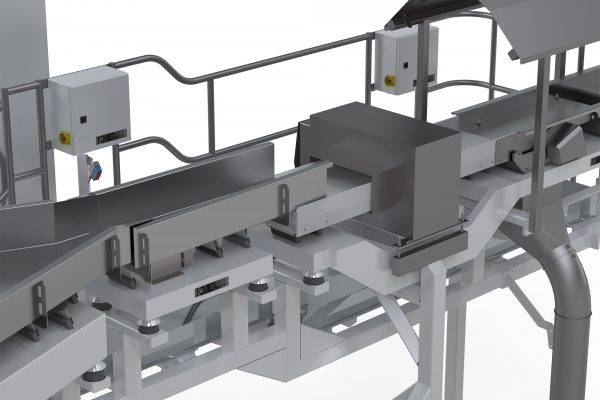

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

Big Bag/Multi Pack Handling

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system for snack manufacturers. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

On Machine Seasoning System

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning System

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Product Blending

Food Vibratory Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Food Vibratory Conveying Systems

Elevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

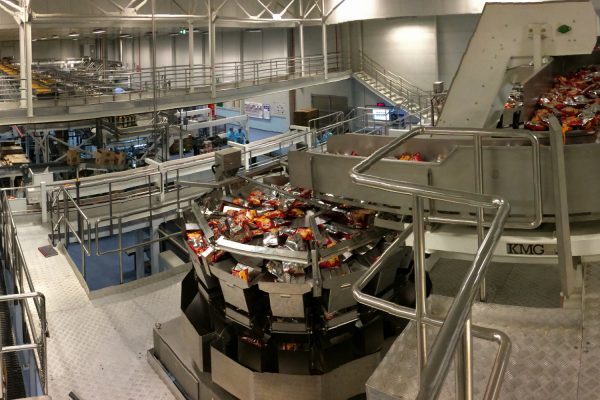

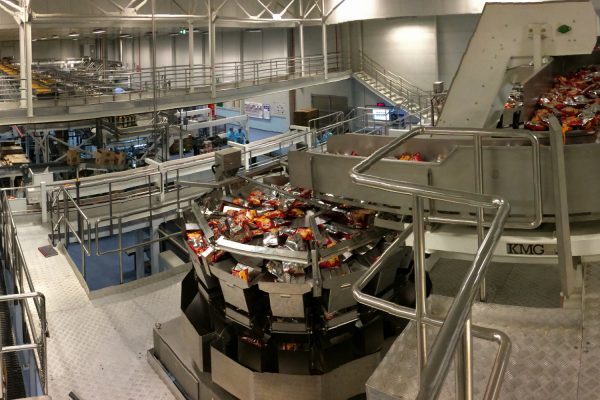

Big Bag/Multi Pack Handling

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special PurposeHandling Products with Care

Applications

Come along and meet the team

Upcoming Trade Shows