Vibratory Conveying Systems

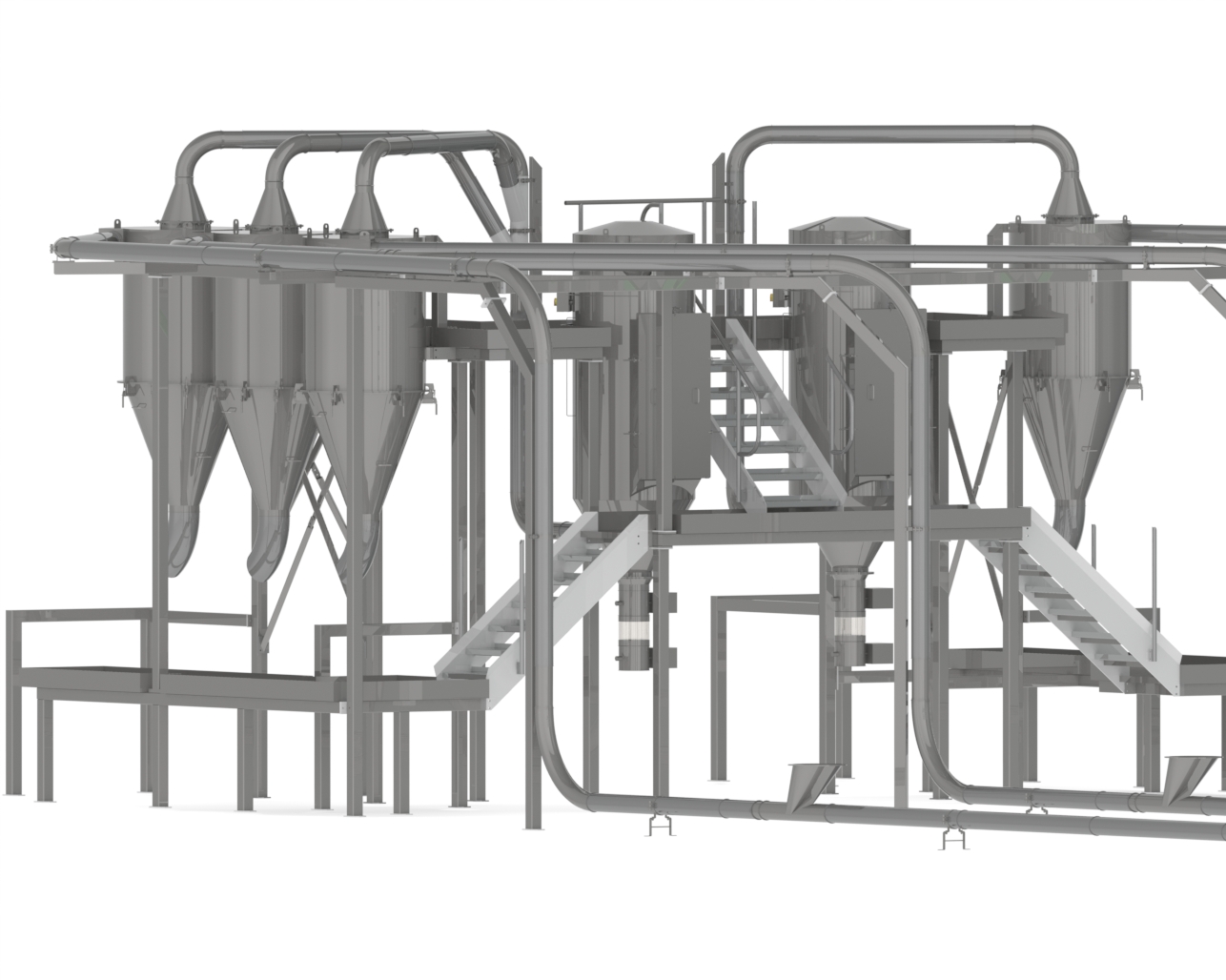

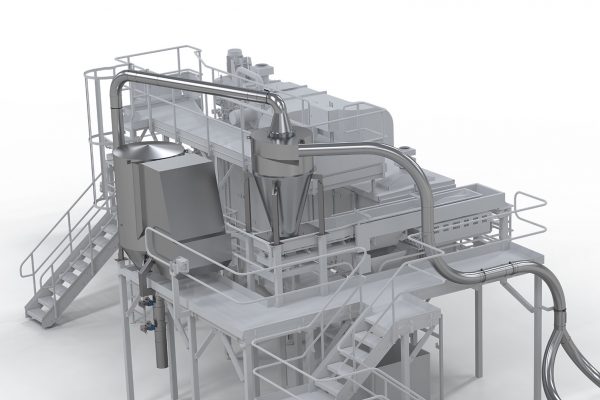

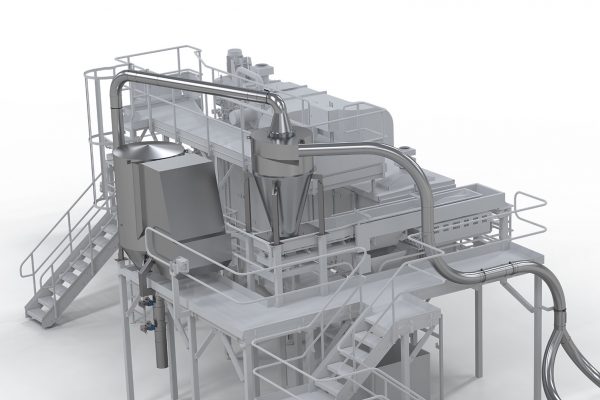

Air Conveying Systems

Air conveying systems are used to transport product or packets swiftly and gently across long distances and can elevate to higher level.

Features

- Enclosed stainless steel tube ducting can carry product through unclassified areas.

- Convey across long distance and changes of elevation

- Dismantlable for cleaning and inspection.

- Only one working part, the fan motor

- Adaptable and flexible design.

- Infeed and discharge via the KMG vibratory conveyor

An air conveyor accepts loose product, typically from an extrusion process or whole packets from a bagging machine. A fan creates a stream of air in the stainless steel sectional tube ducting that carries the product to the deceleration cyclone at the delivery end. The air current is dissipated, and the product decelerates to be carried away by conveyor for further processing. Dust can be contained and removed at the delivery end by a separate filter system.

See where else we use the Air Conveying Systems Machine

Vibratory Conveying Systems with the Air Conveying Systems

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying