- Tank Options: Slurry systems offer single or twin tank configurations, providing flexibility to meet the specific requirements of snack production lines. Various tank sizes are available, enabling manufacturers to choose the capacity that best suits their needs.

- Heated Tanks: To maintain the desired consistency of the slurry mixture, slurry systems may include heated tanks. The heating feature ensures that the oil and seasoning blend remains at the ideal temperature for seamless application onto the snacks.

- Optional Access Platforms: Slurry systems can be equipped with optional access platforms, allowing operators easy access to the tanks for maintenance, cleaning, and ingredient refilling. These platforms enhance operational convenience and efficiency.

- Full Stainless Steel Construction: The construction of Slurry systems is built entirely from stainless steel, ensuring durability, resistance to corrosion, and easy cleaning. This feature supports compliance with industry standards and facilitates hygienic operation.

- Process Flexibility: Slurry systems can be operated in a fully manual mode or fully automatic mode, providing manufacturers with the choice of process control that best suits their production requirements. This adaptability allows for seamless integration into existing snack manufacturing lines.

- Signal-controlled Set Point: Slurry systems offer the convenience of volumetric or gravimetric signal-controlled set points. By integrating with the KMG Flow Weigher, manufacturers can achieve precise and consistent seasoning applications based on weight signals, ensuring accurate flavour distribution.

Seasoning Systems

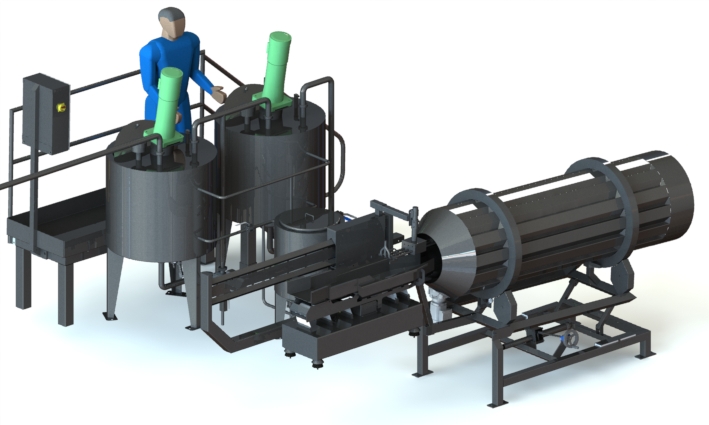

Slurry Systems

In the manufacturing process of extruded snacks, achieving deep flavour absorption can be essential to creating a product that delights consumers' taste buds. One effective method to ensure optimal seasoning is through the use of slurry systems. By combining oil and dry seasoning in a pre-mix and pumping it into the flavour drum, slurry systems deliver consistent and controlled flavour distribution, resulting in a truly satisfying snacking experience.

Features

- Single or twin tank.

- Various tank sizes options.

- Heated tanks.

- Optional access platforms.

- Full stainless steel construction.

- Fully manual to fully automatic process.

- Volumetric or gravimetric signal-controlled set point.

- Standalone or system integrated.

- Infeed and discharge using the KMG Vibratory conveyor

Slurry systems function by pumping a pre-mix of oil and dry seasoning into the flavour drum through nozzles and a lance. The application process can be purely volumetric or controlled through weight signals from the KMG Flow Weigher. To prepare the slurry mixture, a pre-mix tank blends the oil and dry seasoning before transferring it to the holding tank. This ensures a continuous supply of slurry for consistent and uninterrupted flavour application. The slurry is then applied from the holding tank onto the extruded snacks, enveloping them in a flavourful coating. Simultaneously, another batch of slurry is prepared, ensuring a smooth and efficient manufacturing process. By utilising slurry systems, snack manufacturers can overcome the challenge of achieving deep flavour absorption in extruded snacks. The controlled application of the slurry mixture onto the products ensures even distribution of flavour, resulting in a superior snacking experience for consumers. Slurry systems offer a reliable and efficient solution for heavily seasoning extruded snacks. Their versatility, ease of integration, and precise flavour application make them an invaluable asset for snack manufacturers seeking to create products with exceptional taste. With features such as tank options, heated tanks, and signal-controlled set points, slurry systems empower professionals to enhance the flavour absorption of their snack products, ultimately delighting consumers with every bite.

See where else we use the Slurry Systems Machine

Seasoning Systems with the Slurry Systems

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating