- Simplicity and Cost-Effectiveness: Accumulation hoppers operate as intermediaries between two vibratory conveyors. Their simplicity makes them indispensable in their inherency. They can be easily integrated into current conveying structures and are very user-friendly. Furthermore, they provide an affordable means of enhancing production efficiency.

- Hygienic Design: In the food enterprise, hygiene is a paramount factor. These accumulation hoppers are meticulously designed with this crucial aspect in mind. Constructed using food-safe materials, notably chrome steel, adhere to stringent cleanliness and safety standards. This design feature guarantees the product’s uncontaminated journey as it passes through the hopper.

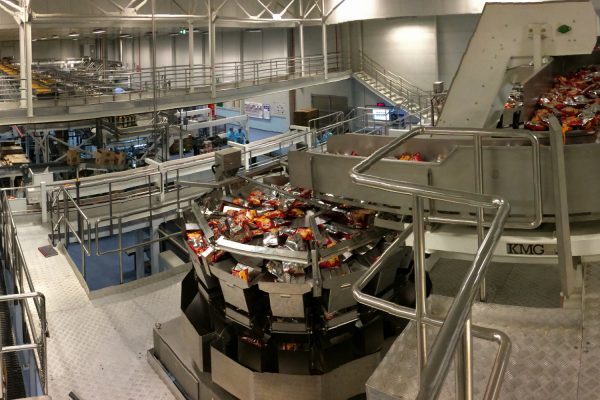

- Preventing Product Fall Damage: Their unique design allows them to accommodate drops in conveying structures preventing products from damage. This feature significantly mitigates the risk of sudden falls and influences that could otherwise harm the product. Maintaining the product’s integrity throughout the production process is crucial for snack food manufacturers committed to delivering a high-quality end product.