- Fully Stainless Steel Hygienic Construction: The KMG Storveyor is built with fully stainless steel hygienic construction. This design ensures compliance with strict hygiene standards, making it suitable for industries such as food processing, pharmaceuticals, and cosmetics. The stainless steel hopper is specially shaped to minimise product compaction, maintaining the integrity and quality of delicate products.

- Gentle on Product: The Storveyor’s design prioritises gentle product handling. This is crucial for maintaining product integrity during the buffering process. By minimising product compaction and employing a positively driven full-width food quality conveyor at the base of the hopper, the Storveyor ensures gentle movement of products towards the discharge point. This gentle handling reduces the risk of damage or degradation, preserving product quality.

- Programmable Operation: The KMG Storveyor offers programmable operation, allowing customisation to suit specific application requirements. The usual operation of the Storveyor follows a “first in first out” principle, ensuring proper product rotation and preventing product degradation due to prolonged storage. Additionally, the Storveyor can be programmed for other functions, such as low or no-drop filling routines for extremely delicate products, providing precise control over the product flow.

- Regulated Product Output: To meet the demands of downstream processes or packaging plants, the Storveyor incorporates one or more KMG vibratory conveyors at the discharge point. These conveyors regulate the output, ensuring a controlled and consistent flow of products. By precisely matching the output to the requirements of subsequent processes, the Storveyor optimises efficiency and minimises bottlenecks.

Vibratory Conveying Systems

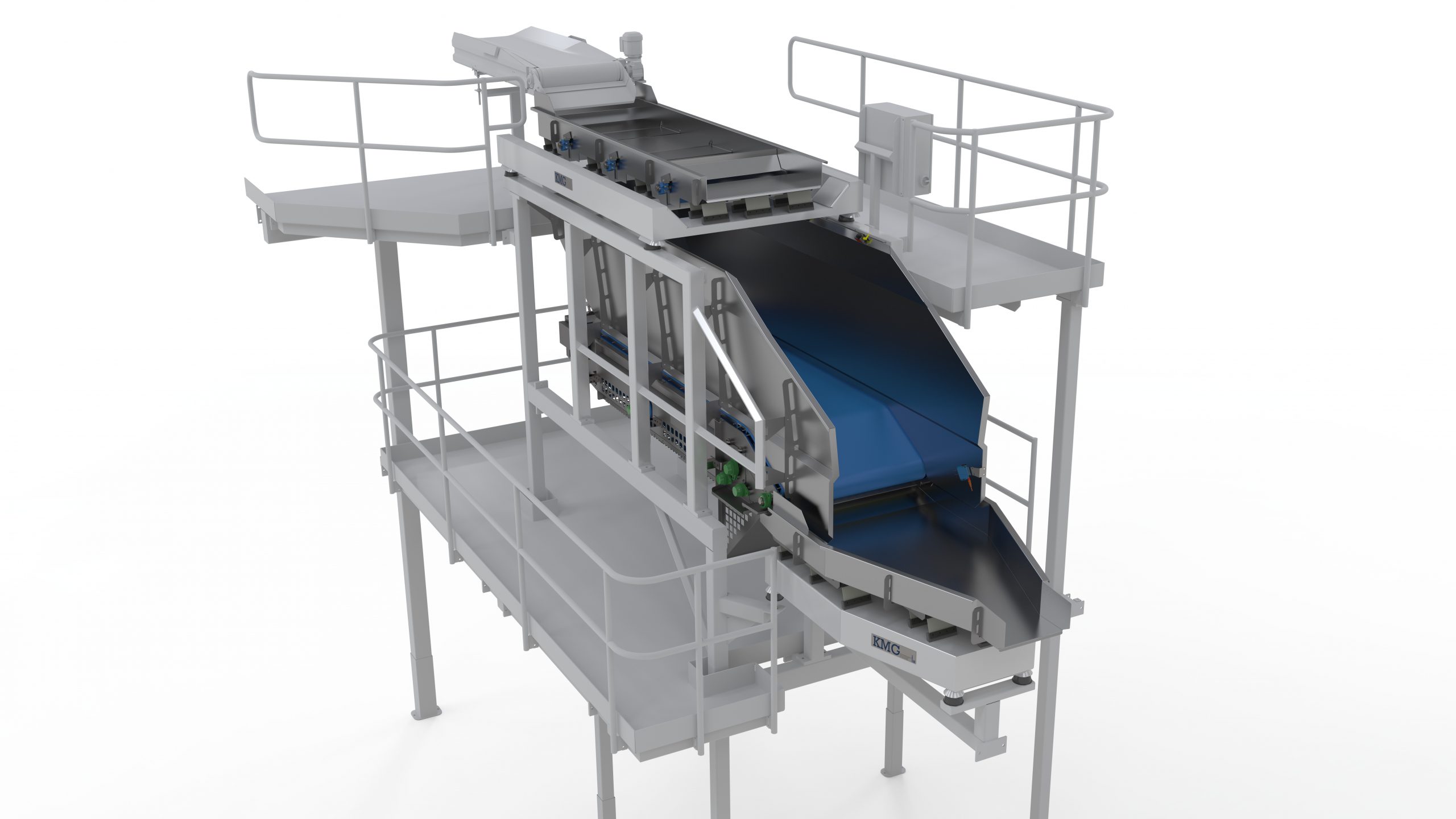

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

Features

- Fully stainless steel hygienic construction

- Gentle on product

- Programable operation

- Regulated product output

- Adaptable design to suit application

- Infeed by a KMG vibratory conveyor

The KMG Storveyor serves as an indispensable component placed between two production processes to facilitate simultaneous acceptance and discharge of products at varying rates. This buffering capability effectively mitigates stoppages or surges in either process, ensuring a smooth and uninterrupted flow of products. Depending on the application requirements, the Storveyor is available in two variants: larger storveyors with a belted design, offering capacities up to 100m³, and smaller vibratory mini-stors with a capacity of up to 2m³. The larger storveyors are suitable for high-capacity operations, while the smaller mini-stores are ideal for smoothing the transition from batch inputs to continuous outputs. The construction of the Storveyor prioritises safety, hygiene, and product integrity. The stainless steel hopper is designed to minimise product compaction and can be equipped with integral hoods and covers to contain dust, heat, or prevent contamination from external sources. This ensures compliance with stringent industry standards and safeguards product quality. The Storveyor's operation is enhanced by level sensors or specialised controls, offering unique features such as low or no-drop filling routines. These features are particularly beneficial for delicate products that require extra care during handling. KMG Storveyor provides professionals in various industries with an efficient and flexible solution for buffering products between processes. With its hygienic construction, gentle product handling, programmable operation, regulated product output, and adaptable design, the Storveyor offers a reliable means of maintaining a consistent flow of products. By leveraging the capabilities of the Storveyor, professionals can enhance efficiency, reduce disruptions, and optimise their production processes, ultimately driving success in their respective industries.

See where else we use the Storveyor Machine

Vibratory Conveying Systems with the Storveyor

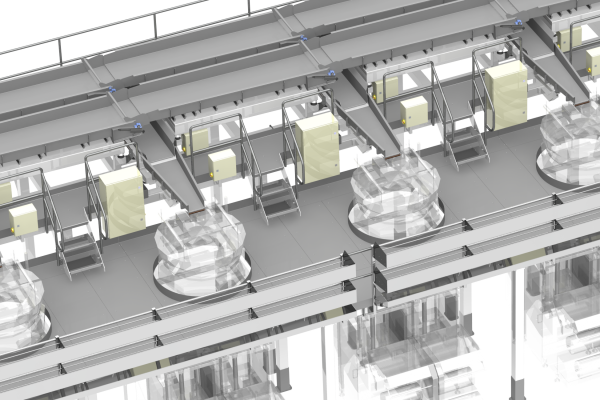

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

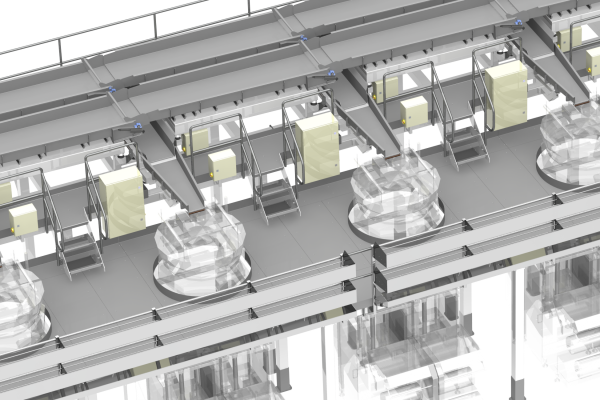

Distribution Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems