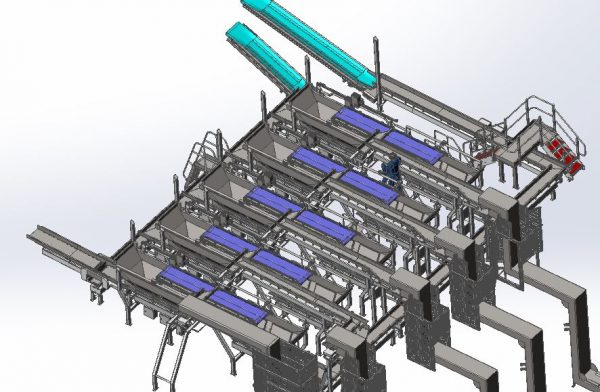

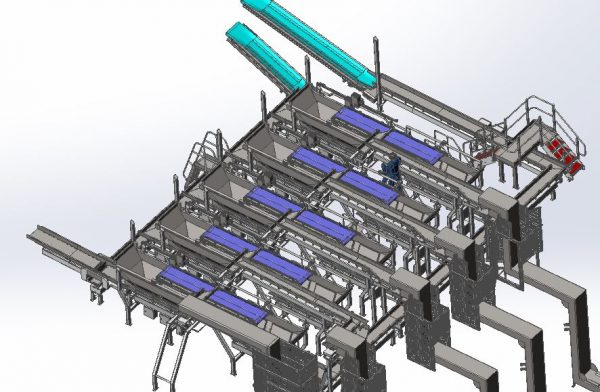

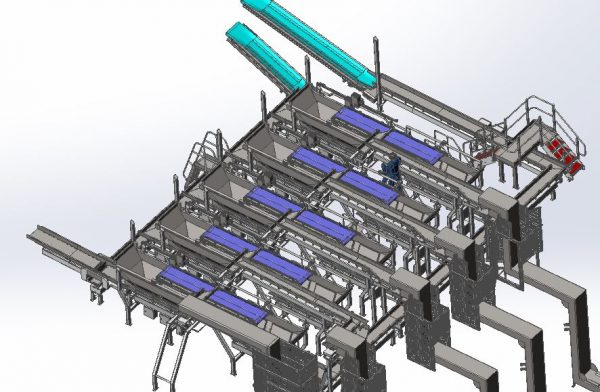

Conveying and Seasoning systems for Fabricated/Stackable Chips

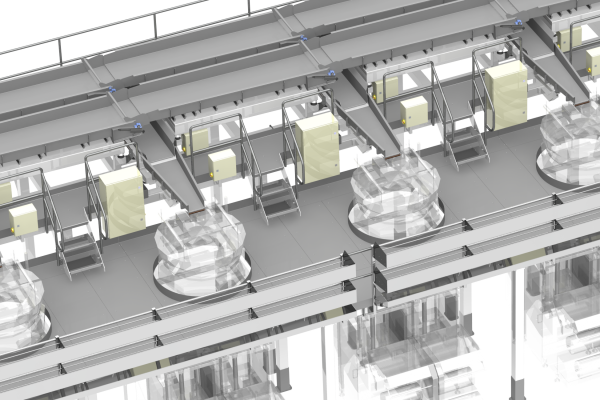

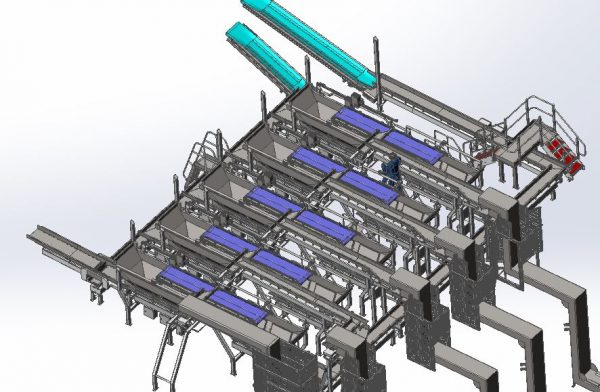

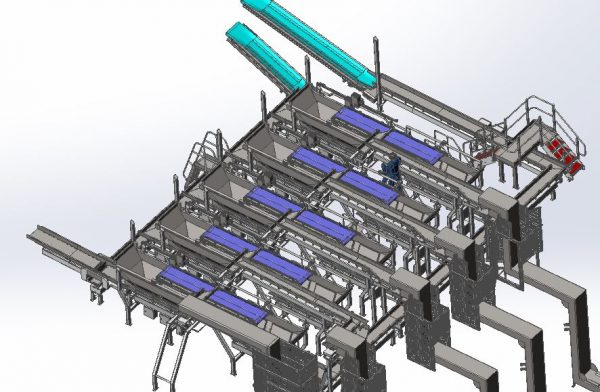

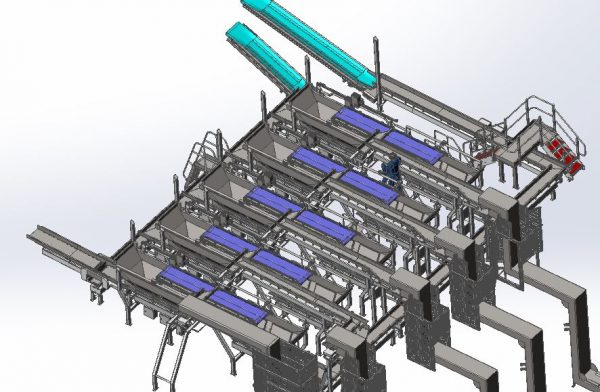

Fabricated/Stackable Chips

A dough is rolled into a long sheet that then passes under a cutter. The cut pieces are then passed through an oven or fryer in lanes. Still in lanes, the chips pass under a seasoning unit, where flavour is applied to the top of the chips. The chips are then gradually slowed down so they start to stack against each other and are then packaged into tubes.

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Seasoning Systems Machines

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

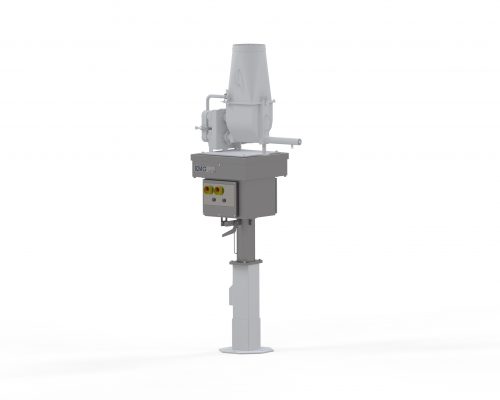

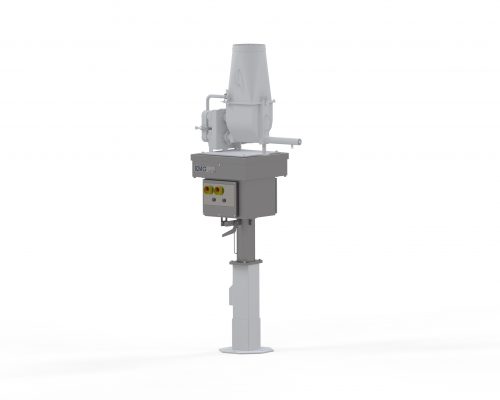

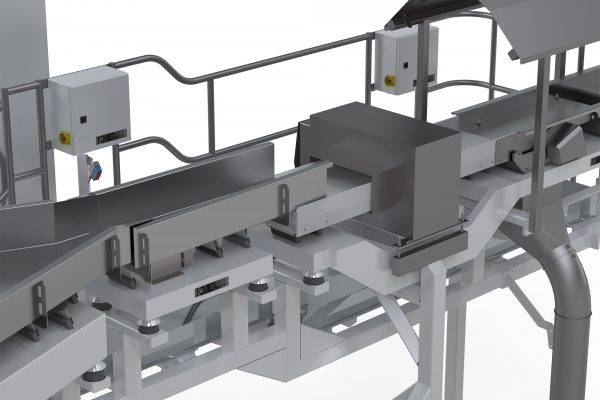

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

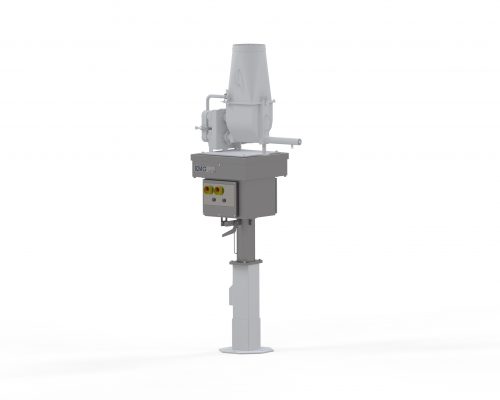

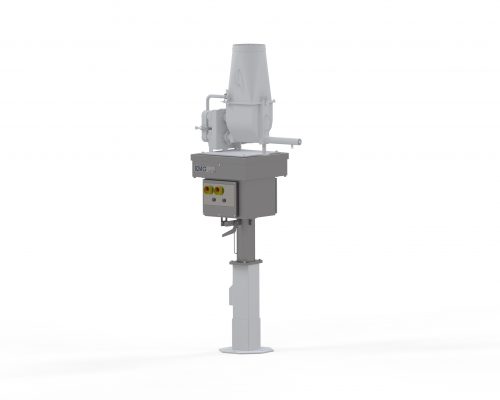

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

Liquid Spray Unit

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Cooling Vibratory ConveyorsKitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

Kitchen Dry Seasoning Machines

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

Proportioning Control Vibratory Conveyor

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Air Filtration Unit (AFU)

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Smart Seasoning ValidationElevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor Systems

Elevating Conveyor Systems Machines

Flighted Belt Elevators

KMG's Flighted Belt Elevators (FBE) are designed with safety, hygiene, and efficiency principles in mind, offering a solution that not only meets but exceeds the rigorous standards of the food processing sector. These elevators provide a safe, clean, and gentle means of transporting products from one level to another, ensuring that food products maintain their integrity and quality throughout the production process.

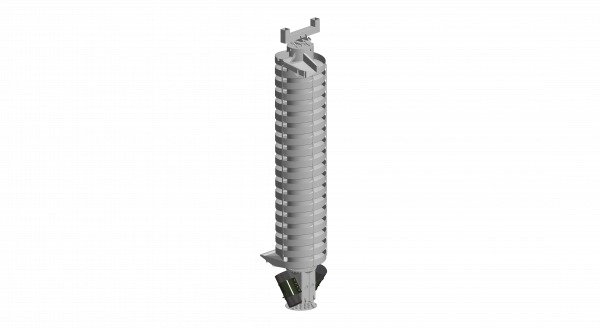

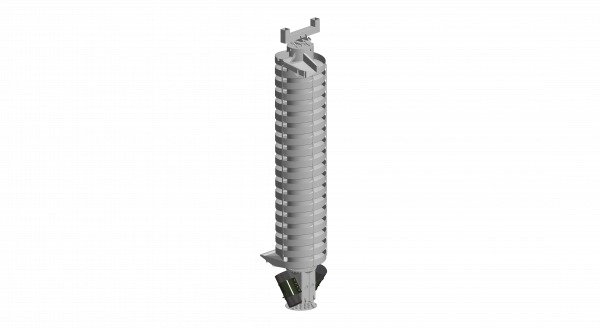

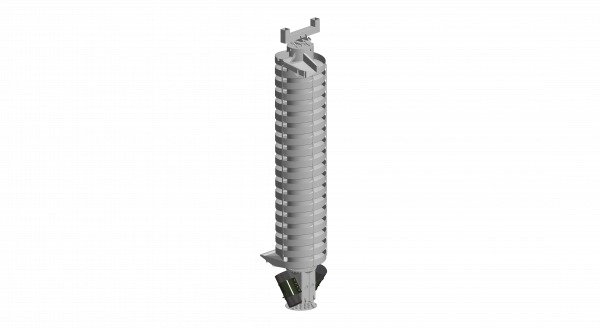

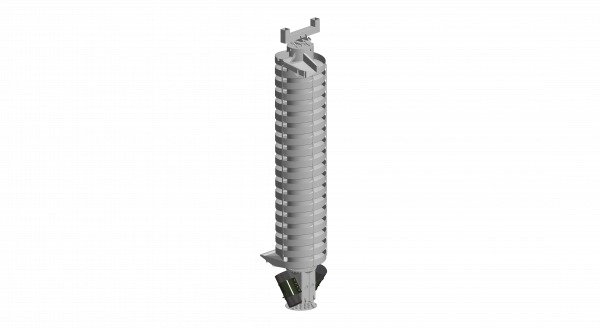

Spiral Elevator

Designed to gently lift products up to 7 meters, this innovative equipment offers professionals in various industries a cost-effective and efficient way to transport goods. In this blog post, we will delve into the features and benefits of the spiral elevator, highlighting its fully stainless steel construction, low maintenance design, and versatility in heating and cooling configurations.

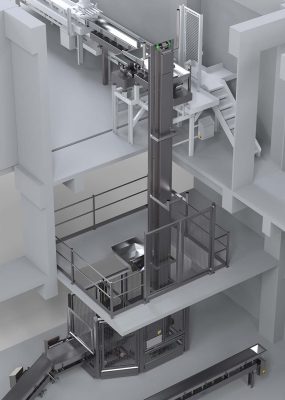

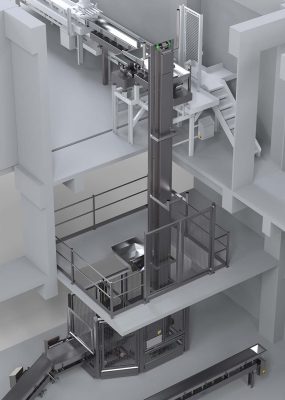

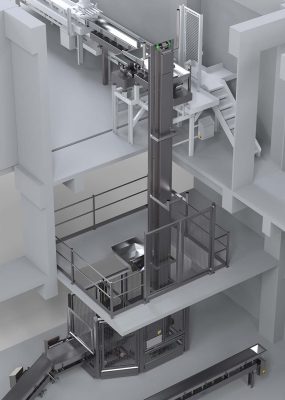

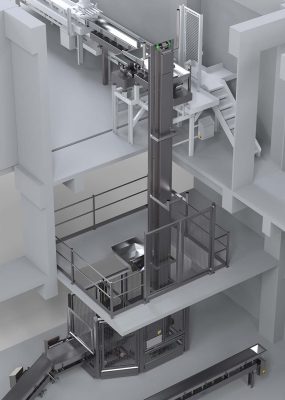

Bucket Lift and Tip

Designed for elevating snack food the KMG Bucket Lift and Tip replaces traditional bucket and belt type elevators with an all stainless steel construction quick change machine to raise product from process to packing.

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Flighted Belt Elevators

KMG's Flighted Belt Elevators (FBE) are designed with safety, hygiene, and efficiency principles in mind, offering a solution that not only meets but exceeds the rigorous standards of the food processing sector. These elevators provide a safe, clean, and gentle means of transporting products from one level to another, ensuring that food products maintain their integrity and quality throughout the production process.

Flighted Belt Elevators

Spiral Elevator

Designed to gently lift products up to 7 meters, this innovative equipment offers professionals in various industries a cost-effective and efficient way to transport goods. In this blog post, we will delve into the features and benefits of the spiral elevator, highlighting its fully stainless steel construction, low maintenance design, and versatility in heating and cooling configurations.

Spiral Elevator

Bucket Lift and Tip

Designed for elevating snack food the KMG Bucket Lift and Tip replaces traditional bucket and belt type elevators with an all stainless steel construction quick change machine to raise product from process to packing.

Bucket Lift and Tip

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Breakfast Cereal Vibratory conveyorsDistribution Systems

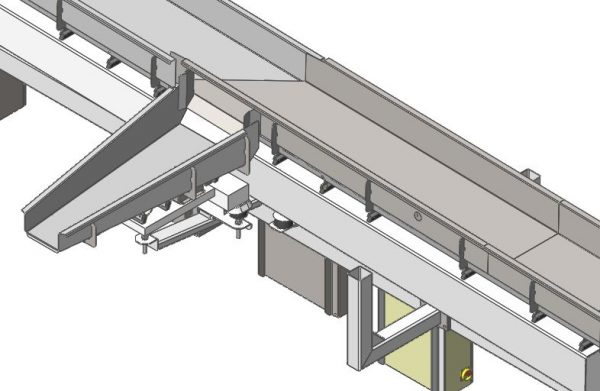

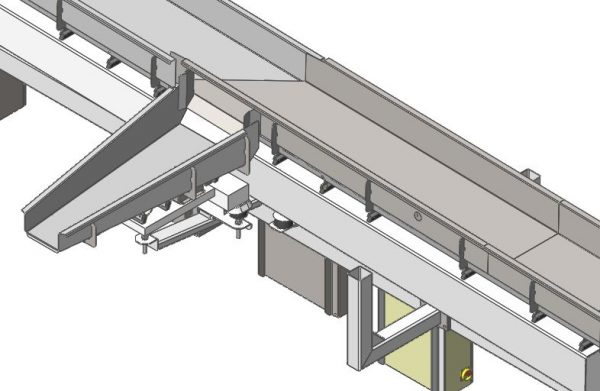

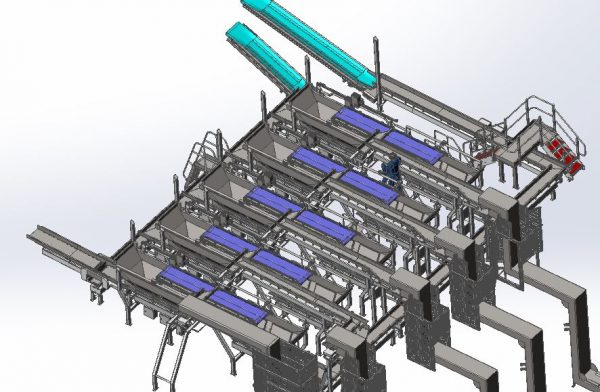

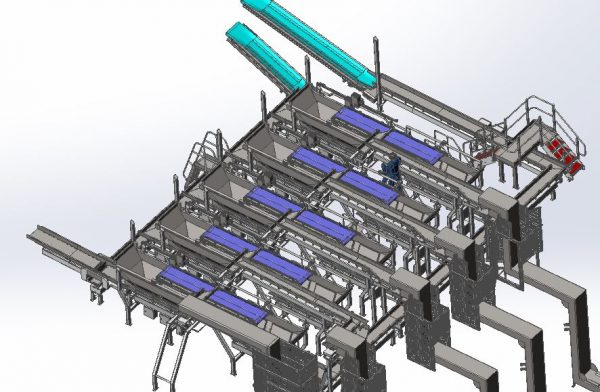

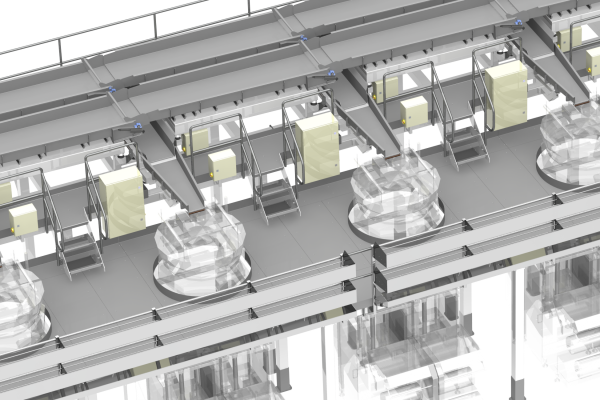

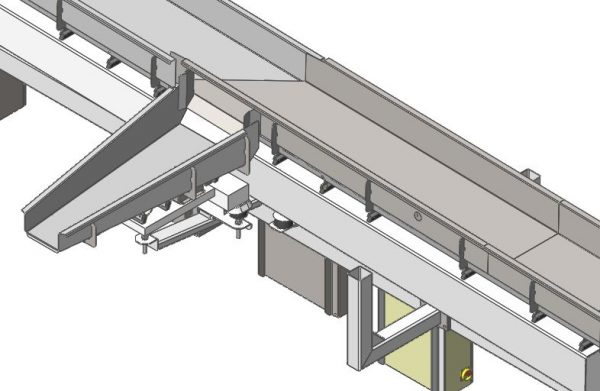

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems

Distribution Systems Machines

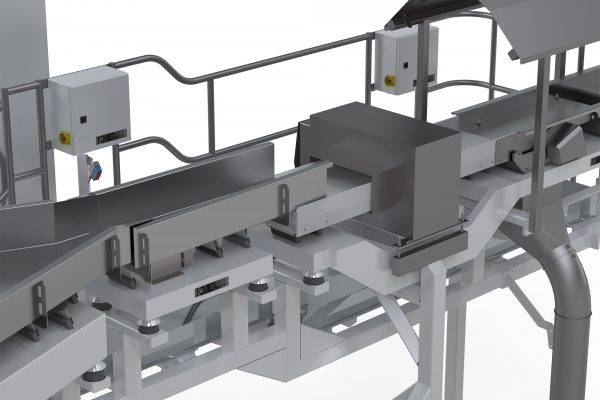

Gated Vibratory Conveyors

KMG Gated Vibratory Conveyors offer an innovative solution that delivers reliable and efficient product transfer, making them a cornerstone in various industries, from seasoning applications to packing processes, ensuring precision and control over the transfer of the product.

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

KMG Autoflow Plus

KMG introduces the patented Autoflow Plus, a gateless distribution system that minimises product drops and eliminates moving parts. This innovative system is a game-changer for the industry, offering a new level of control, efficiency and precise distribution./l

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

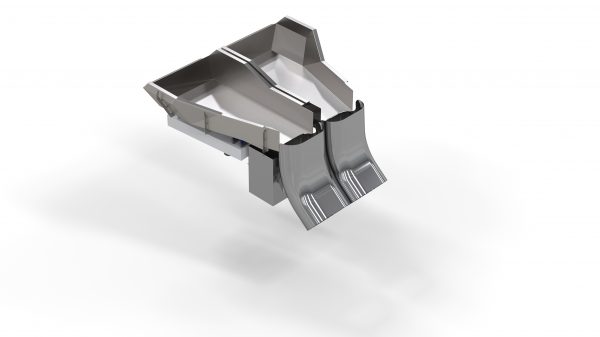

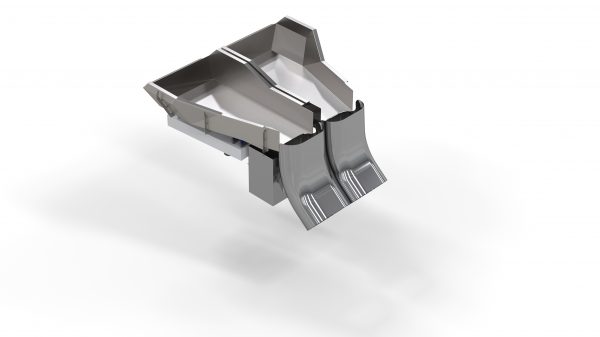

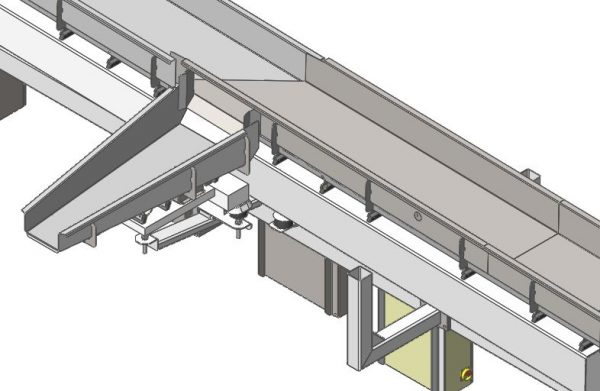

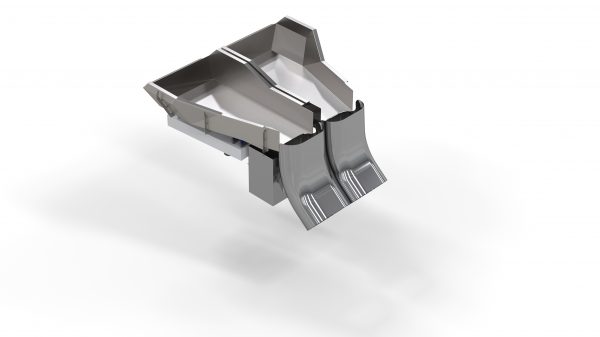

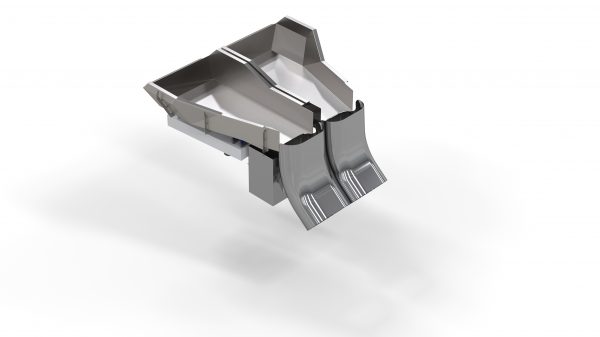

Servo Assisted Proportioning Chute

When it comes to proportioning product feed into multiple directions, space constraints can often pose a challenge. However, the KMG Proportioning Chute offers a solution that is both efficient and space-saving. In this blog post, we will explore the features and benefits of the Servo Assisted Proportioning Chute, highlighting its accurate servo-controlled rotation, easy cleaning and maintenance, inherent safety, and seamless product changeover capabilities.

KMG Drop Weigher

Managing waste is useful aspect of the process of snack production, and its accurate measurement is essential. KMG introduces the Drop Weigher, a solution that provides real-time and precise weight measurements for waste on food production lines. Let's explore this innovative system in detail.

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Weigher Feed Vibratory Conveyor

KMG weigher feed vibratory conveyors are used to give manufacturers a controlled feed of product on to the multi-head weigher. KMG Systems design and manufacture weigher feed vibratory conveyors specifically for the food industry. With our 50 years of experience, we design our equipment to be hygienic, easy to clean and easy to maintain. We know that you will be operating to the highest hygiene standards and we take that into account with our designs.

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Gated Vibratory Conveyors

KMG Gated Vibratory Conveyors offer an innovative solution that delivers reliable and efficient product transfer, making them a cornerstone in various industries, from seasoning applications to packing processes, ensuring precision and control over the transfer of the product.

Gated Vibratory Conveyors

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

In Line Storage

KMG Autoflow Plus

KMG introduces the patented Autoflow Plus, a gateless distribution system that minimises product drops and eliminates moving parts. This innovative system is a game-changer for the industry, offering a new level of control, efficiency and precise distribution./l

KMG Autoflow Plus

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

Storveyor

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

KMG AutoGlide® (Horizontal Motion Conveyors)

Servo Assisted Proportioning Chute

When it comes to proportioning product feed into multiple directions, space constraints can often pose a challenge. However, the KMG Proportioning Chute offers a solution that is both efficient and space-saving. In this blog post, we will explore the features and benefits of the Servo Assisted Proportioning Chute, highlighting its accurate servo-controlled rotation, easy cleaning and maintenance, inherent safety, and seamless product changeover capabilities.

Servo Assisted Proportioning Chute

KMG Drop Weigher

Managing waste is useful aspect of the process of snack production, and its accurate measurement is essential. KMG introduces the Drop Weigher, a solution that provides real-time and precise weight measurements for waste on food production lines. Let's explore this innovative system in detail.

KMG Drop Weigher

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Vibratory Conveyors

Weigher Feed Vibratory Conveyor

KMG weigher feed vibratory conveyors are used to give manufacturers a controlled feed of product on to the multi-head weigher. KMG Systems design and manufacture weigher feed vibratory conveyors specifically for the food industry. With our 50 years of experience, we design our equipment to be hygienic, easy to clean and easy to maintain. We know that you will be operating to the highest hygiene standards and we take that into account with our designs.

Weigher Feed Vibratory Conveyor

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Breakfast Cereal Vibratory conveyors

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Spigot Discharge Vibratory Conveyor

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Tubular Vibratory Conveyors

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Laning Vibratory Conveyor

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Spreader Vibratory Conveyor

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Mobile Vibratory ConveyorsProcess Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Process Preparation Area Machines Machines

Pellet Bulk Handling

KMG pellet bulk handling systems provide a controlled and consistent feed of raw pellet products into the fryer.

Potato Preparation Area

To meet the demands of this industry, KMG has developed a range of innovative mechanically driven machines for the Potato Preparation Area. These mechanically driven machines offer superior performance in harsh process environments, ensuring the smooth transfer of whole potatoes to and from peelers, sorters, and grading equipment. With years of engineering design expertise, KMG provides reliable and efficient systems that deliver exceptional results.

Kettle / Potato Chips Batch Flow Control

In the world of snack food manufacturing, where precision and consistency are paramount, achieving an efficient batch flow control process is critical. KMG introduces an innovative solution for controlling batches of potatoes fed into the frying process, a key element in the production of kettle and potato chips. This technology ensures a consistent and efficient process, making it a game-changer for manufacturers in this industry.

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Potato Preparation Vibratory Conveyors

Potato processing is a tough environment for equipment and the KMG range of potato preparation vibratory conveyors are designed precisely for that environment. These machines ensure the smooth transfer of whole potatoes from the flume to peelers, sorters, de-watering and grading equipment.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Pellet Bulk Handling

KMG pellet bulk handling systems provide a controlled and consistent feed of raw pellet products into the fryer.

Pellet Bulk Handling

Potato Preparation Area

To meet the demands of this industry, KMG has developed a range of innovative mechanically driven machines for the Potato Preparation Area. These mechanically driven machines offer superior performance in harsh process environments, ensuring the smooth transfer of whole potatoes to and from peelers, sorters, and grading equipment. With years of engineering design expertise, KMG provides reliable and efficient systems that deliver exceptional results.

Potato Preparation Area

Kettle / Potato Chips Batch Flow Control

In the world of snack food manufacturing, where precision and consistency are paramount, achieving an efficient batch flow control process is critical. KMG introduces an innovative solution for controlling batches of potatoes fed into the frying process, a key element in the production of kettle and potato chips. This technology ensures a consistent and efficient process, making it a game-changer for manufacturers in this industry.

Kettle / Potato Chips Batch Flow Control

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Product Blending

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Vibratory Conveyors

Potato Preparation Vibratory Conveyors

Potato processing is a tough environment for equipment and the KMG range of potato preparation vibratory conveyors are designed precisely for that environment. These machines ensure the smooth transfer of whole potatoes from the flume to peelers, sorters, de-watering and grading equipment.

Potato Preparation Vibratory Conveyors

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Spreader Vibratory ConveyorSpecial Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose

Special Purpose Machines

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Inspection Vibratory Conveyor

Inspection Vibratory Conveyors enable manual inspection of conveyed product, giving an opportunity to remove any substandard product and maintain quality standards. This has a lower investment cost than expensive mechanical or optical sorting process equipment.

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Grading Vibratory Conveyor

Grading vibratory conveyors are used to safely and hygienically separate product by size. As part of your manufacturing process it can be desirable to grade and separate undersize and oversize product. A KMG grading vibratory conveyor will be designed to use a suitable mesh or screen. This could be punched holes, bars, mesh or proprietary screens. A machine like this will always be designed and built to your specification, using our decades of grading experience.

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Product Blending

Inspection Vibratory Conveyor

Inspection Vibratory Conveyors enable manual inspection of conveyed product, giving an opportunity to remove any substandard product and maintain quality standards. This has a lower investment cost than expensive mechanical or optical sorting process equipment.

Inspection Vibratory Conveyor

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Cooling Vibratory Conveyors

Grading Vibratory Conveyor

Grading vibratory conveyors are used to safely and hygienically separate product by size. As part of your manufacturing process it can be desirable to grade and separate undersize and oversize product. A KMG grading vibratory conveyor will be designed to use a suitable mesh or screen. This could be punched holes, bars, mesh or proprietary screens. A machine like this will always be designed and built to your specification, using our decades of grading experience.

Grading Vibratory Conveyor

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Mobile Vibratory Conveyors

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Laning Vibratory Conveyor

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Spigot Discharge Vibratory Conveyor

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Tubular Vibratory Conveyors

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Spreader Vibratory Conveyor

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning SystemsSeasoning Systems Machines

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

Liquid Spray Unit

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Cooling Vibratory Conveyors

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry SeasoningKitchen Dry Seasoning Machines

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

Proportioning Control Vibratory Conveyor

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Air Filtration Unit (AFU)

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Smart Seasoning Validation

Elevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor SystemsElevating Conveyor Systems Machines

Flighted Belt Elevators

KMG's Flighted Belt Elevators (FBE) are designed with safety, hygiene, and efficiency principles in mind, offering a solution that not only meets but exceeds the rigorous standards of the food processing sector. These elevators provide a safe, clean, and gentle means of transporting products from one level to another, ensuring that food products maintain their integrity and quality throughout the production process.

Spiral Elevator

Designed to gently lift products up to 7 meters, this innovative equipment offers professionals in various industries a cost-effective and efficient way to transport goods. In this blog post, we will delve into the features and benefits of the spiral elevator, highlighting its fully stainless steel construction, low maintenance design, and versatility in heating and cooling configurations.

Bucket Lift and Tip

Designed for elevating snack food the KMG Bucket Lift and Tip replaces traditional bucket and belt type elevators with an all stainless steel construction quick change machine to raise product from process to packing.

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Flighted Belt Elevators

KMG's Flighted Belt Elevators (FBE) are designed with safety, hygiene, and efficiency principles in mind, offering a solution that not only meets but exceeds the rigorous standards of the food processing sector. These elevators provide a safe, clean, and gentle means of transporting products from one level to another, ensuring that food products maintain their integrity and quality throughout the production process.

Flighted Belt Elevators

Spiral Elevator

Designed to gently lift products up to 7 meters, this innovative equipment offers professionals in various industries a cost-effective and efficient way to transport goods. In this blog post, we will delve into the features and benefits of the spiral elevator, highlighting its fully stainless steel construction, low maintenance design, and versatility in heating and cooling configurations.

Spiral Elevator

Bucket Lift and Tip

Designed for elevating snack food the KMG Bucket Lift and Tip replaces traditional bucket and belt type elevators with an all stainless steel construction quick change machine to raise product from process to packing.

Bucket Lift and Tip

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Breakfast Cereal Vibratory conveyors

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution SystemsDistribution Systems Machines

Gated Vibratory Conveyors

KMG Gated Vibratory Conveyors offer an innovative solution that delivers reliable and efficient product transfer, making them a cornerstone in various industries, from seasoning applications to packing processes, ensuring precision and control over the transfer of the product.

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

KMG Autoflow Plus

KMG introduces the patented Autoflow Plus, a gateless distribution system that minimises product drops and eliminates moving parts. This innovative system is a game-changer for the industry, offering a new level of control, efficiency and precise distribution./l

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

Servo Assisted Proportioning Chute

When it comes to proportioning product feed into multiple directions, space constraints can often pose a challenge. However, the KMG Proportioning Chute offers a solution that is both efficient and space-saving. In this blog post, we will explore the features and benefits of the Servo Assisted Proportioning Chute, highlighting its accurate servo-controlled rotation, easy cleaning and maintenance, inherent safety, and seamless product changeover capabilities.

KMG Drop Weigher

Managing waste is useful aspect of the process of snack production, and its accurate measurement is essential. KMG introduces the Drop Weigher, a solution that provides real-time and precise weight measurements for waste on food production lines. Let's explore this innovative system in detail.

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Weigher Feed Vibratory Conveyor

KMG weigher feed vibratory conveyors are used to give manufacturers a controlled feed of product on to the multi-head weigher. KMG Systems design and manufacture weigher feed vibratory conveyors specifically for the food industry. With our 50 years of experience, we design our equipment to be hygienic, easy to clean and easy to maintain. We know that you will be operating to the highest hygiene standards and we take that into account with our designs.

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Gated Vibratory Conveyors

KMG Gated Vibratory Conveyors offer an innovative solution that delivers reliable and efficient product transfer, making them a cornerstone in various industries, from seasoning applications to packing processes, ensuring precision and control over the transfer of the product.

Gated Vibratory Conveyors

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

In Line Storage

KMG Autoflow Plus

KMG introduces the patented Autoflow Plus, a gateless distribution system that minimises product drops and eliminates moving parts. This innovative system is a game-changer for the industry, offering a new level of control, efficiency and precise distribution./l

KMG Autoflow Plus

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

Storveyor

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

KMG AutoGlide® (Horizontal Motion Conveyors)

Servo Assisted Proportioning Chute

When it comes to proportioning product feed into multiple directions, space constraints can often pose a challenge. However, the KMG Proportioning Chute offers a solution that is both efficient and space-saving. In this blog post, we will explore the features and benefits of the Servo Assisted Proportioning Chute, highlighting its accurate servo-controlled rotation, easy cleaning and maintenance, inherent safety, and seamless product changeover capabilities.

Servo Assisted Proportioning Chute

KMG Drop Weigher

Managing waste is useful aspect of the process of snack production, and its accurate measurement is essential. KMG introduces the Drop Weigher, a solution that provides real-time and precise weight measurements for waste on food production lines. Let's explore this innovative system in detail.

KMG Drop Weigher

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Vibratory Conveyors

Weigher Feed Vibratory Conveyor

KMG weigher feed vibratory conveyors are used to give manufacturers a controlled feed of product on to the multi-head weigher. KMG Systems design and manufacture weigher feed vibratory conveyors specifically for the food industry. With our 50 years of experience, we design our equipment to be hygienic, easy to clean and easy to maintain. We know that you will be operating to the highest hygiene standards and we take that into account with our designs.

Weigher Feed Vibratory Conveyor

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Breakfast Cereal Vibratory conveyors

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Spigot Discharge Vibratory Conveyor

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Tubular Vibratory Conveyors

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Laning Vibratory Conveyor

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Spreader Vibratory Conveyor

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Mobile Vibratory Conveyors

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area MachinesProcess Preparation Area Machines Machines

Pellet Bulk Handling

KMG pellet bulk handling systems provide a controlled and consistent feed of raw pellet products into the fryer.

Potato Preparation Area

To meet the demands of this industry, KMG has developed a range of innovative mechanically driven machines for the Potato Preparation Area. These mechanically driven machines offer superior performance in harsh process environments, ensuring the smooth transfer of whole potatoes to and from peelers, sorters, and grading equipment. With years of engineering design expertise, KMG provides reliable and efficient systems that deliver exceptional results.

Kettle / Potato Chips Batch Flow Control

In the world of snack food manufacturing, where precision and consistency are paramount, achieving an efficient batch flow control process is critical. KMG introduces an innovative solution for controlling batches of potatoes fed into the frying process, a key element in the production of kettle and potato chips. This technology ensures a consistent and efficient process, making it a game-changer for manufacturers in this industry.

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Potato Preparation Vibratory Conveyors

Potato processing is a tough environment for equipment and the KMG range of potato preparation vibratory conveyors are designed precisely for that environment. These machines ensure the smooth transfer of whole potatoes from the flume to peelers, sorters, de-watering and grading equipment.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Pellet Bulk Handling

KMG pellet bulk handling systems provide a controlled and consistent feed of raw pellet products into the fryer.

Pellet Bulk Handling

Potato Preparation Area

To meet the demands of this industry, KMG has developed a range of innovative mechanically driven machines for the Potato Preparation Area. These mechanically driven machines offer superior performance in harsh process environments, ensuring the smooth transfer of whole potatoes to and from peelers, sorters, and grading equipment. With years of engineering design expertise, KMG provides reliable and efficient systems that deliver exceptional results.

Potato Preparation Area

Kettle / Potato Chips Batch Flow Control

In the world of snack food manufacturing, where precision and consistency are paramount, achieving an efficient batch flow control process is critical. KMG introduces an innovative solution for controlling batches of potatoes fed into the frying process, a key element in the production of kettle and potato chips. This technology ensures a consistent and efficient process, making it a game-changer for manufacturers in this industry.

Kettle / Potato Chips Batch Flow Control

Product Blending