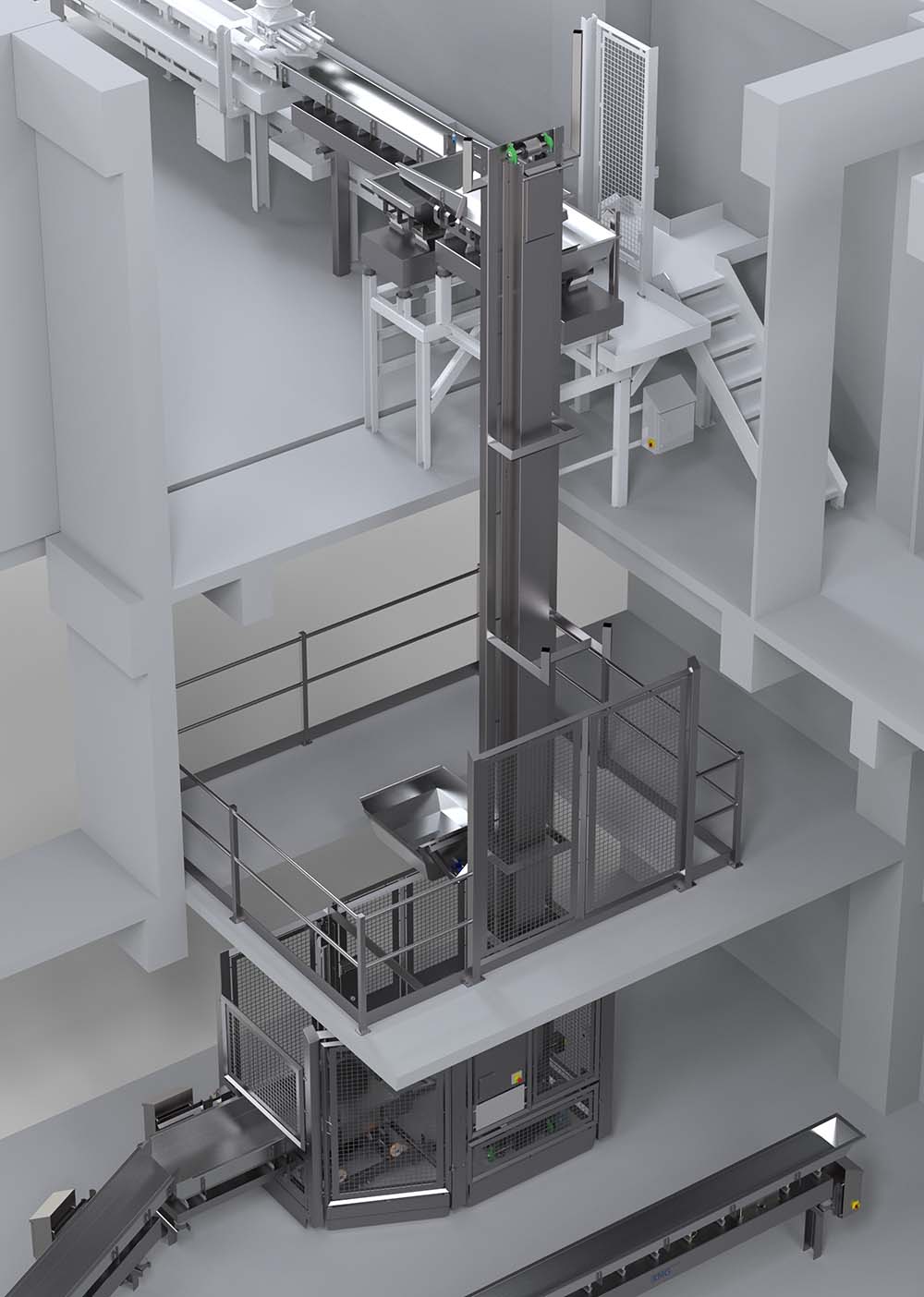

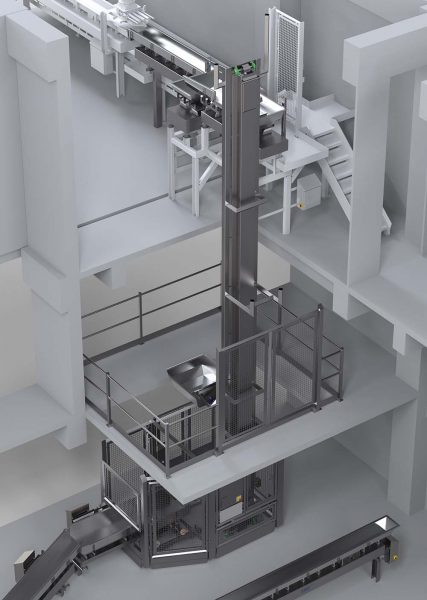

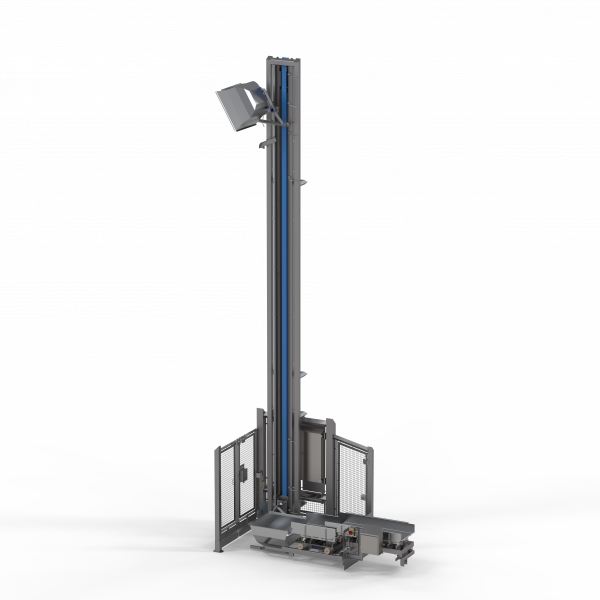

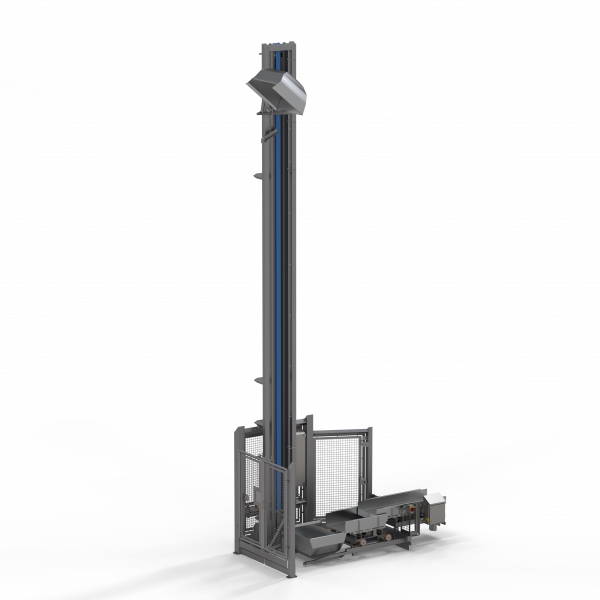

Efficiently elevating bulk materials is made easier with Bucket Lift and Tip systems. These systems employ use a single stainless-steel hopper which is used to lift and move the snack materials smoothly and vertically.

At KMG, we understand the value of time and efficiency in the industrial sector. The Bucket Lift and Tip Conveying System is designed to optimise material handling processes, accelerating overall productivity. The system is designed with LEAN principles in mind and allows for a super-fast change over, offering a seamless and efficient solution for bulk material transportation.

At KMG we will seamlessly integrate our Bucket Lift and Tip Conveying System into existing production lines, providing a first-class upgrade for businesses looking to optimise their product handling processes. The flexible design allows customisation to meet the specific needs of diverse industries, accommodating various product types. Whether you’re dealing with cereals, snacks, chips petfood, or other bulk materials, our system is engineered to handle them with ease and precision.

The system’s robust design enables it to handle a wide range of materials. By automating the lifting and conveying processes, the system ensures a continuous flow of materials, minimising downtime and maximising output.

Our Bucket Lift and Tip Conveying System can be customised to meet specific needs, ensuring seamless integration into existing production lines. With various options for capacity, height, and configuration, businesses can optimise the system to suit their operational demands.

To minimise downtime and keep operations running smoothly, our Bucket Lift and Tip Conveying System is designed for easy maintenance and monitoring. The user-friendly interface allows for real-time system monitoring, ensuring quick detection and resolution of any issues. With regular maintenance and proper upkeep, our system guarantees long-term reliability, helping businesses maintain uninterrupted production cycles.