The KMG proportioning control vibratory conveyor enables your base product to be cleanly and accurately fed to different in kitchen seasoning loops.

At KMG Systems, we understand that precise material handling is crucial for optimising production and minimising waste. Our Proportioning Control Vibratory Conveyor takes accuracy to the next level. By integrating advanced control systems and sensor technologies, we ensure the precise proportioning and distribution of materials,

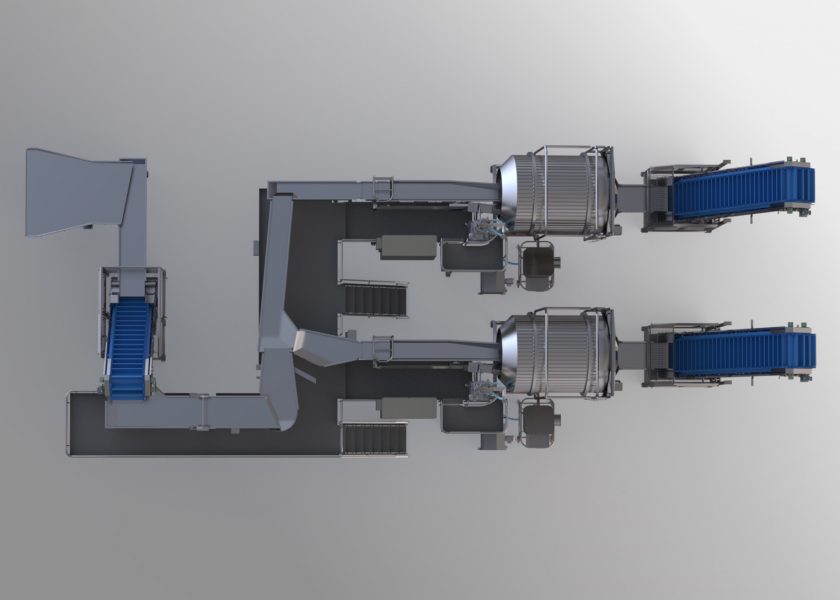

The Proportioning Control Vibratory Conveyor developed by KMG Systems is a game-changer for industries requiring precise control over product flow rates. Our advanced technology allows for unparalleled accuracy in proportioning and distributing base product, enabling manufacturers to optimise their production processes. This conveyor system eliminates the challenges associated with manual handling and traditional conveyor systems, providing a seamless and efficient solution.

One of the key advantages of the KMG Proportioning Control Vibratory Conveyor is its ability to deliver precise proportioning control. Equipped with intelligent sensors and advanced control algorithms, this system ensures accurate distribution of materials in real-time. The proportional feeding capability allows for consistent material flow rates, reducing the risk of overfeeding or underfeeding, and eliminating costly production errors. By maintaining a constant and controlled flow, manufacturers can enhance product quality, reduce waste, and improve overall operational efficiency.

Our Proportioning Control Vibratory Conveyor is designed to integrate seamlessly with existing production lines, minimising downtime and disruption during installation. Additionally, the system’s user-friendly interface and intuitive controls make operation and maintenance straightforward.

Every company has unique material handling requirements, and our Proportioning Control Vibratory Conveyor is designed to meet those needs. With customisable features and adaptable configurations, we can tailor our system to suit your specific application.

Our Proportioning Control Vibratory Conveyor offers unparalleled accuracy, efficiency, and flexibility for industries dealing with bulk materials. By integrating this cutting-edge technology into their operations, companies can optimise production processes, improve product quality, and enhance overall operational efficiency.