- Safe, Silent, and Hygienic: The KMG Flavour Vacuum Lift (VLS) prioritises safety, silence, and hygiene in its design. These characteristics are crucial in food manufacturing, where cleanliness and efficiency go hand in hand.

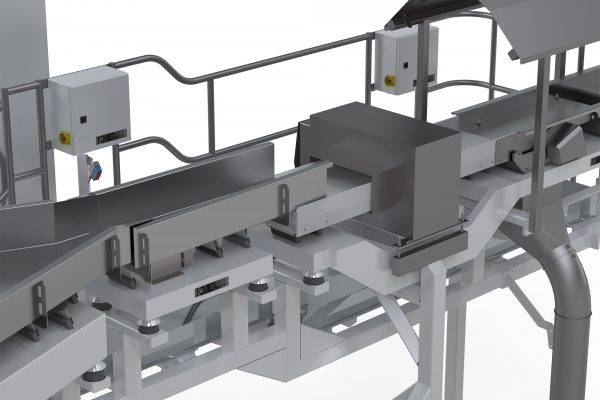

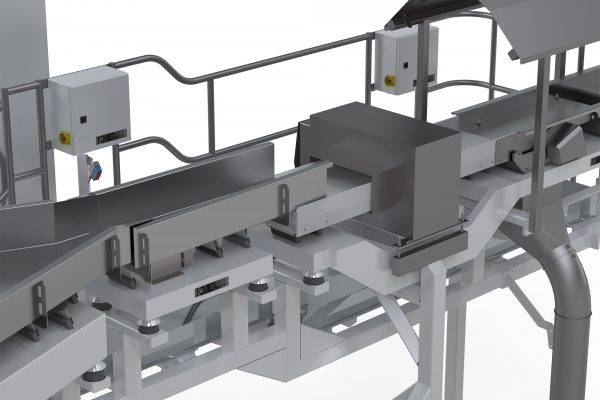

- Quick Change Parts: When it comes to maintenance and cleaning, the VLS makes it easy. It’s designed for quick changeovers, and a single operator can strip it down, ensuring minimal downtime and operational efficiency.

- Contact Parts: The VLS is constructed with materials that meet the highest standards of food safety. This includes contact parts made from stainless steel or food-grade plastic, keeping the conveyed powders uncontaminated.

- Minimal Moving Parts: With no high-level motor and minimal moving components, the VLS is not only quieter but also less prone to wear and tear. This is a significant advantage in terms of maintenance and reliability.

- Works in Conjunction with KMG Loss in Weight: For even more precision in ingredient handling, the VLS can be synchronised perfectly with the KMG Loss in Weight system, ensuring the accurate delivery of powders.

- Synchronises Perfectly with the KMG PDU Flavour Feeder: To streamline the flavouring process, the VLS works in perfect harmony with the KMG PDU Flavour Feeder. This synchronisation optimises the production line’s efficiency and precision.

- Bulk Hopper with KMG Air Filtration Unit: To maintain hygiene and air quality, the VLS can be equipped with a KMG Air Filtration Unit, further ensuring that the conveyed powders remain pristine.

- Minimal Guarding: Unlike traditional screw elevators that typically have moving agitators, the VLS requires minimal guarding, enhancing both safety and operational visibility.

- Complete Powder Utilisation: One standout feature of the VLS is its efficiency in utilising the conveyed powders. Unlike traditional screw elevators that often leave behind significant residues, the VLS ensures that nearly all the seasoning or product is removed from the hopper when running out.

Seasoning Systems

Vibratory Conveying Systems

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Features

- The KMG Flavour Vacuum Lift (VLS) is Safe, silent and hygienic.

- Quick change parts and easily stripped down by a single operator

- Contact parts Stainless steel or food grade plastic

- No high level motor and minimal moving parts

- Works in conjunction with KMG Loss in Weight

- Synchronises perfectly with the KMG PDU Flavour feeder

- Bulk hopper available with KMG Air Filtration Unit

- Minimal guarding because there is no moving agitator

- All seasoning/product is removed from the KMG Flavour Vacuum Lift (VLS) hopper when running out compared to a traditional screw elevator would leave 1 to 2 kg in the bottom of the hopper when disassembled for cleaning.

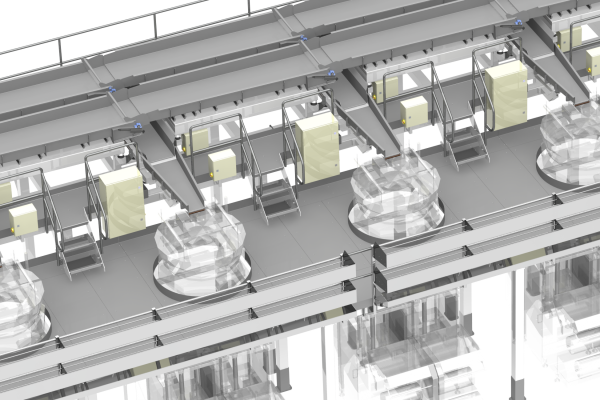

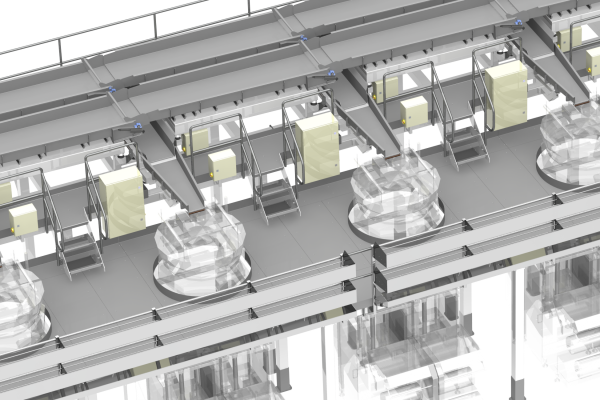

The KMG Flavour Vacuum Lift (VLS) is an essential element for snack food manufacturing. Installed at high levels in the production process, the VLS conveys batches of powder on demand. Its design facilitates straightforward disassembly for cleaning, which is crucial in maintaining the highest hygiene standards. The ground-level conical bulk hopper, constructed from stainless steel, adds mobility and durability to the system. An out-of-balance motor is used to agitate the powder within the hopper, promoting even flow. This motor can be installed either actively on the side of the hopper unit or passively on a static platform where the hopper can be docked. Sanitary clamps are used for all fittings and ducting, making assembly and disassembly a breeze. This design detail is not just convenient but also aligns with the stringent hygiene standards of the food industry. KMG Flavour Vacuum Lift (VLS) ensures that every batch of powder is delivered with precision and cleanliness, maintaining the integrity of your products and the trust of your consumers. With features that prioritise safety, hygiene, and efficiency, the VLS is a testament to KMG's commitment to elevating the standards of snack food manufacturing.

See where else we use the Flavour Vacuum Lift (VLS) Machine

Seasoning Systems with the Flavour Vacuum Lift (VLS)

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

On Machine Seasoning

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Vibratory Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Vibratory Conveying Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

On Machine Seasoning

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Vibratory Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Vibratory Conveying Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose