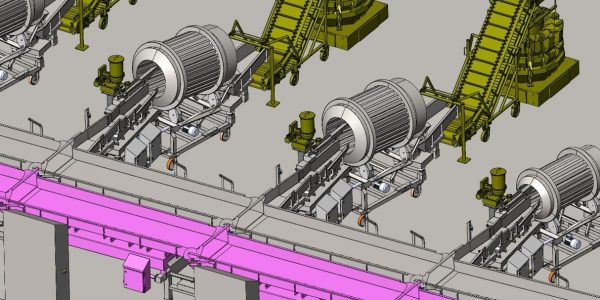

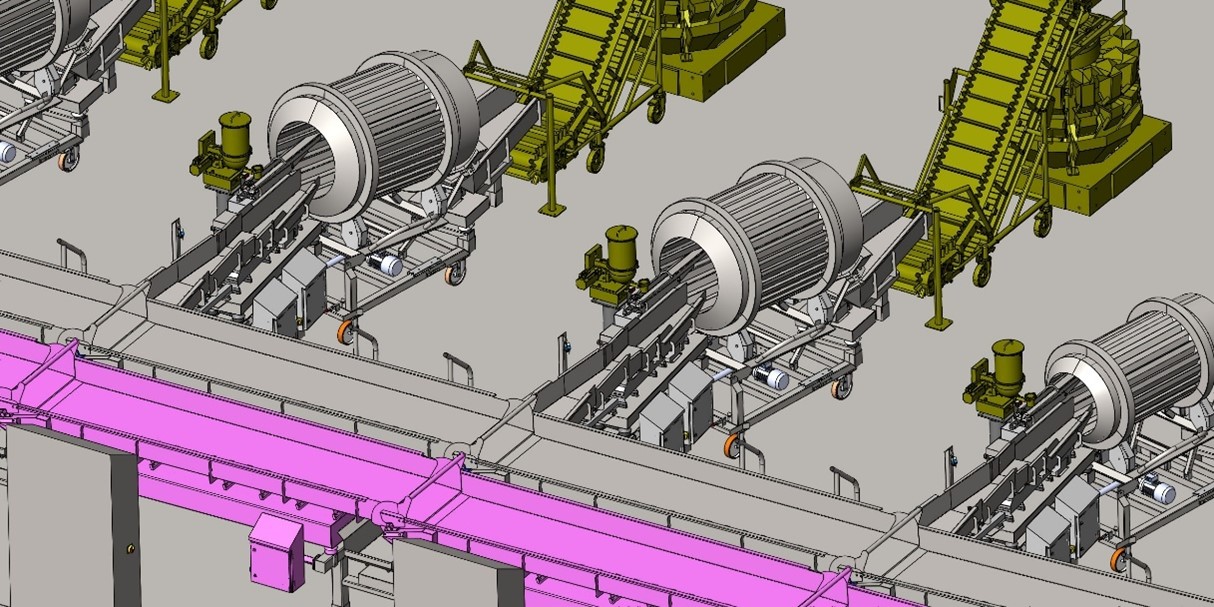

KMG Systems were recently tasked with developing a hygienic, quick release scarf feeder pan to allow cleaning “out of place”. Our customer purchased nine KMG on machine seasoning systems (OMS) for their site in mainland Europe. KMG first pioneered On Machine Seasoning Systems in the early 1980s and have continued to develop them ever since.

Although typically each OMS “loop” can be cleaned in less than 20 minutes whilst the other stations production is unaffected, our customer wanted to streamline the cleaning process further and optimise the time taken as much as possible.

Part of the KMG remit was to design & manufacture components compatible with one another across all nine OMS seasoning loops.

Design Brief

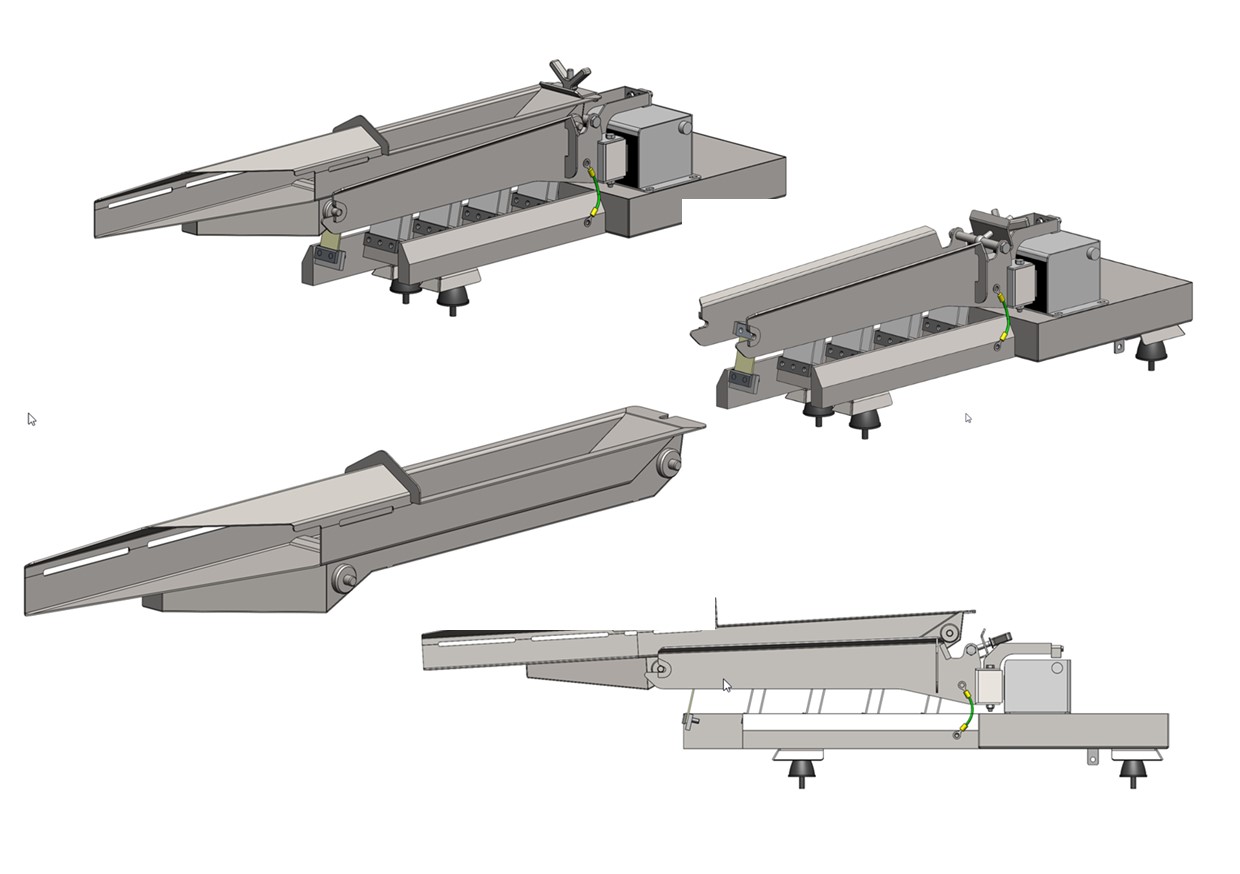

- Removable Scarf pan for cleaning out of place

- 750mm and 1000mm diameter seasoning drum compatibility

- Open clean design and construction

- Minimal weight

- Compatibility with any corresponding carriage, present and future

KMG’s team of experienced design and development engineers identified the challenges associated with this brief, breaking them down into five considerations.

Mechanical Clearances

Compact and simplified design necessary to achieve sufficient clearances accounting for drum size, positional and fabrication tolerances.

Hygienic Design

Design for technical capability of clean welding within compact arrangement.

Open Construction

Ability to clean in factory parts washer and no more enclosed than weigher bucket/seasoning tube.

Reduced Components

Avoidance of unnecessary covers/hinges & supports that introduce additional maintenance or cleaning concerns.

Compatibility

Any scarf pan made at any time will fit any carriage made at any time. With these design considerations in mind a working prototype was developed.

- Integrated cover (removable cover available if required)

- Enclosed tip limited to in-drum section only

- Enclosed surfaces reduced to minimum

- No concealed crevices

- Mirror finish internal surfaces

- Laser welded construction

- 6kg weight (removable pan)

After close consultation and collaboration with our customer around the prototype a final design was agreed.

The collaborative nature of this product development demonstrates how KMG Systems combine innovation and specialist knowledge to ensure that we provide the cleanest, safest, most reliable systems that combine high accuracy and gentle product handling with flexibility.

KMG is the global leader in the design and manufacture of conveying and seasoning systems for the food industry. We have 50 years of experience and the best engineers in the industry.