- KMG Patented Technology: The heart of FlowWeigherTM’s innovation lies in its patented technology. This system’s unique design sets it apart from other flow rate measuring systems, providing unparalleled accuracy and reliability.

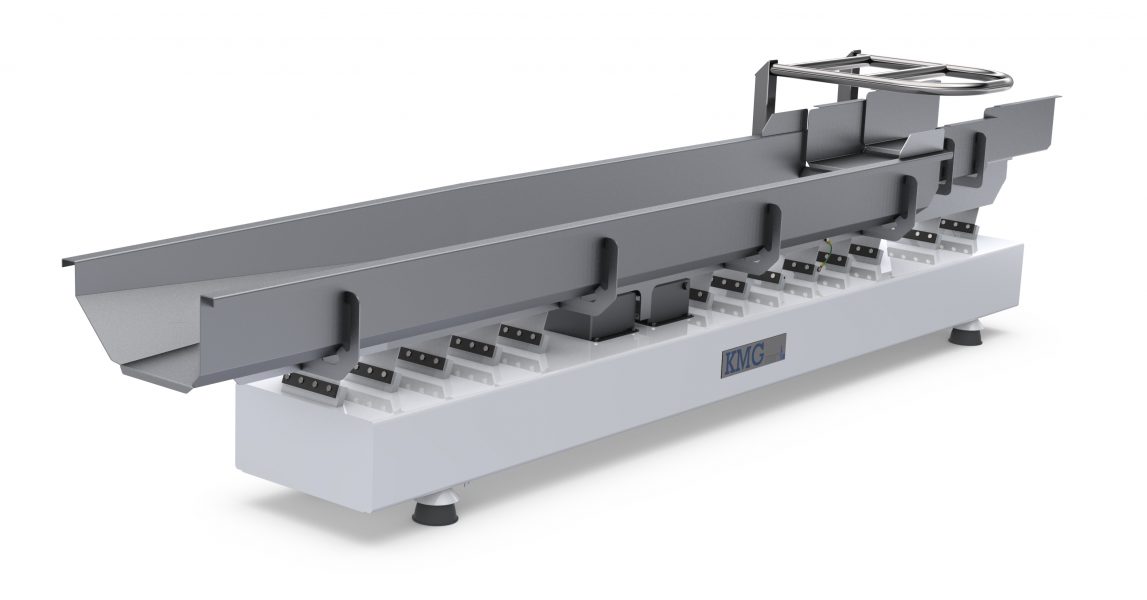

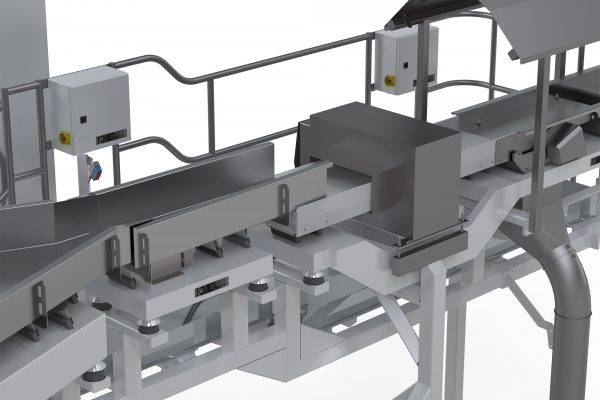

- Weighs Section of Counter-Balanced Trough: The FlowWeigherTM takes precision seriously. By weighing a section of the counter-balanced trough where the product sits, it offers highly accurate measurements without any significant product drop.

- In-Line Product Measurement: Unlike some other systems that measure the entire conveyor, the FlowWeigherTM focuses solely on what’s in the tray. This in-line product measurement guarantees precise data and eliminates the need for estimation.

- Hygienic Vibratory Conveyor Design: Maintaining hygiene in the manufacturing process is essential, particularly in the food industry. The FlowWeigherTM‘s hygienic vibratory conveyor design aligns with industry standards and ensures that your production environment remains clean and uncontaminated.

- Robust Construction: The FlowWeigherTM is built to last. Its robust construction can withstand the rigour of the manufacturing environment, ensuring durability and longevity.

- Load Cell Offload Design: This design feature minimises the risk of damage. The load cell offload design contributes to the system’s overall reliability and safety.

- Simple Calibration Procedure: Calibration is straightforward with the FlowWeigherTM, simplifying maintenance and ensuring that the system remains highly accurate.

- Main PLC Controlled – Simple Operator/Engineer Interface: A user-friendly interface is vital for efficient operation. The FlowWeigherTM‘s interface, controlled by a main PLC, offers simplicity for operators and engineers alike.

Seasoning Systems

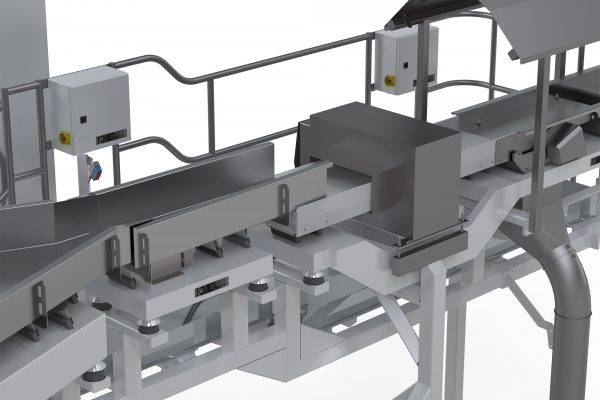

FlowWeigherTM

The KMG FlowWeigherTM, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

Features

- KMG Patented Technology

- Weighs section of counter balanced trough

- In-line Product Measurement

- No significant product drop

- Hygienic Vibratory Conveyor Design

- Robust Construction

- Load cell Offload design prevents damage risk

- Simple Calibration Procedure

- Main PLC Controlled- Simple operator/engineer interface

The KMG FlowWeigherTM is a game-changer in the world of production. Its ability to measure precisely what's in the tray, rather than estimating or weighing the entire conveyor, is a testament to its innovation. This approach allows it to provide real-time flow rate data, ensuring that your processes are optimised for accuracy and efficiency. The user interface is designed with operators in mind, providing real-time numerical and graphical flow rate data. With the touch-sensitive screen, operators can effortlessly navigate through various menu options, including recipe-based settings for tare and auto-tare. A secure calibration mode with a password requirement ensures data integrity and accuracy. The FlowWeigherTM offers a 4-20mA output corresponding to the flow rates, allowing for proportional control of other downstream equipment such as powder dispensers or liquid spray units. In the competitive world of manufacturing, where every measurement counts, the KMG FlowWeigherTM is the tool you need to achieve unparalleled precision, ensuring the quality and efficiency of your production processes.

See where else we use the FlowWeigherTM Machine

Seasoning Systems with the FlowWeigherTM

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

On Machine Seasoning

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating

Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Conveying Systems

Elevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor Systems

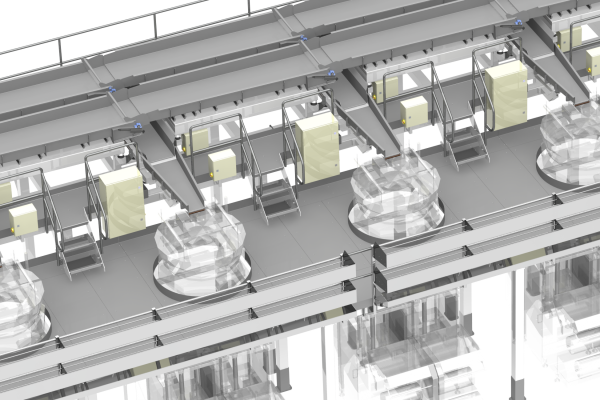

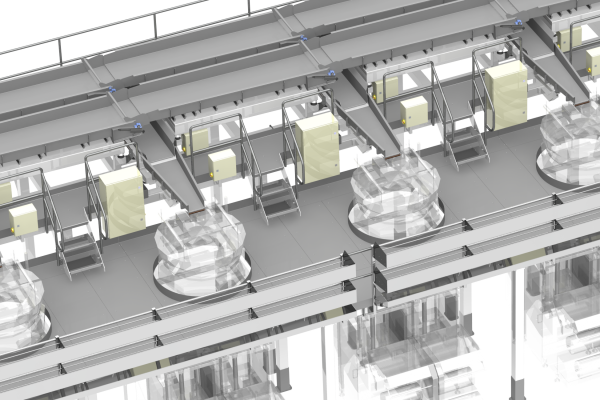

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

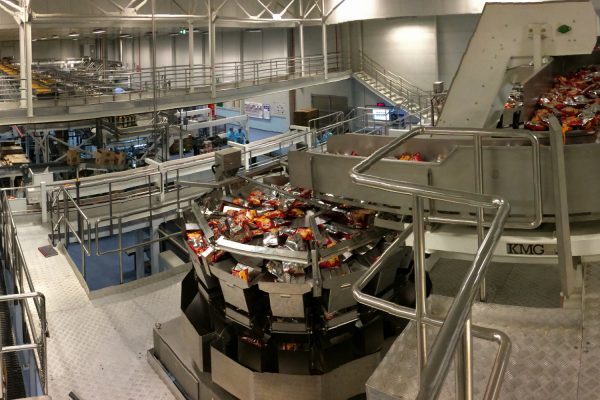

Big Bag/Multi Pack Handling

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying

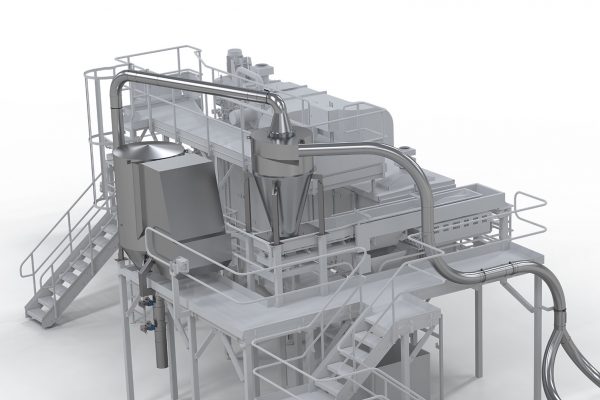

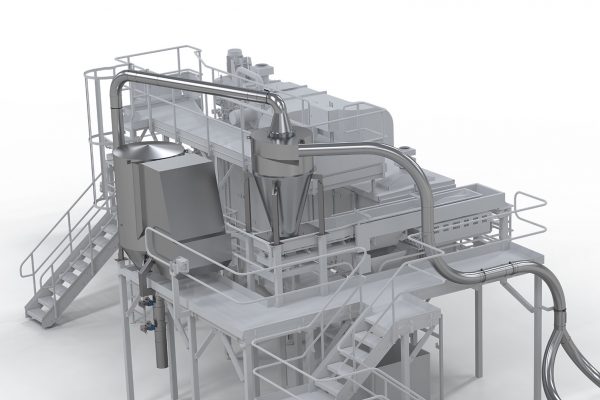

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose

Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Seasoning Systems

Kitchen Dry Seasoning

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Kitchen Dry Seasoning

On Machine Seasoning

KMG On Machine Seasoning System (OMS) offers producers flexibility where multiple outlets are fed with product and seasoned directly above the packaging machine. Each On Machine Seasoning System (OMS) is fully gravimetric and can be cleaned in less than 20 minutes whilst to other stations production is unaffected.

On Machine Seasoning

Oil & Dry Seasoning

Using the features of KMG Liquid spray units and dry seasoning systems KMG has perfected the oil and dry seasoning of Tortilla Chips, Popcorn, Nuts and Extruded products for the worlds leading snack manufacturers.

Oil & Dry Seasoning

Slurry Coating

Extruded snacks may need to be heavily seasoned for deep flavour absorption into the product. Where separate oil and dry application systems can’t be used, KMG slurry coating systems may be the alternative.

Slurry Coating

Conveying Systems

Present in over 100 countries KMG is a major supplier of specialised conveying systems to multi-national and local food manufacturers . Our customers rely on KMG systems to safely transport their products from process to packaging using vibratory conveyors that are renowned for their excellent performance, durability and low energy usage – providing good value for money and superb reliability.

Conveying Systems

Elevating Conveyor Systems

The KMG range of elevating conveyor systems consists of Vibratory Spiral, Bucket Elevator, Single Bucket Lift and Tip (BLT) and Flighted Belt type. Each design is available in a range of sizes appropriate to product throughput and bulk density.

Elevating Conveyor Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors.

Distribution Systems

End of Line Packing

Working with our partners KMG supplies and integrates end of line packing solutions into modular control panels or separate power panels as part of our distribution system.

End of Line Packing

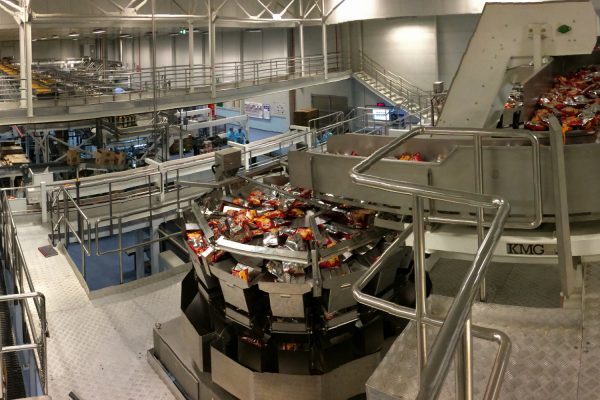

Big Bag/Multi Pack Handling

KMG snack food multi-pack handling systems can produce 2,3,4,5,6 same or multi-mix packs in a multi-pack format. Packets are fed from storage hoppers by either air blowing or belt elevation and fed in a controlled and streamed manner to the weigh head. KMG has designed and built a purpose built product reject system positioned between the weigher and bagmaker for multi-pack reject.

Big Bag/Multi Pack Handling

Air Conveying

Along with mechanical handling systems KMG specialise in the air transport of friable snack food products such as dry pellets and extruded collets. Product is placed into a venturi and carried in ducting in a mass of air pushed by a blower.

Air Conveying

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

Special Purpose