- Optimising Packing Capability: KMG In-Line Storage systems are strategically sized to enable in-line storage of processed products. This feature is designed to support smooth reel changes or adjustments on packing machines without causing system starvation or overflow.

- Programmed and Tested at KMG: The systems are meticulously programmed and rigorously tested by KMG, ensuring reliable and seamless performance.

- Versatile with Snack Foods: In-line storage systems can be used with a variety of snack foods, making them adaptable to different product lines and requirements.

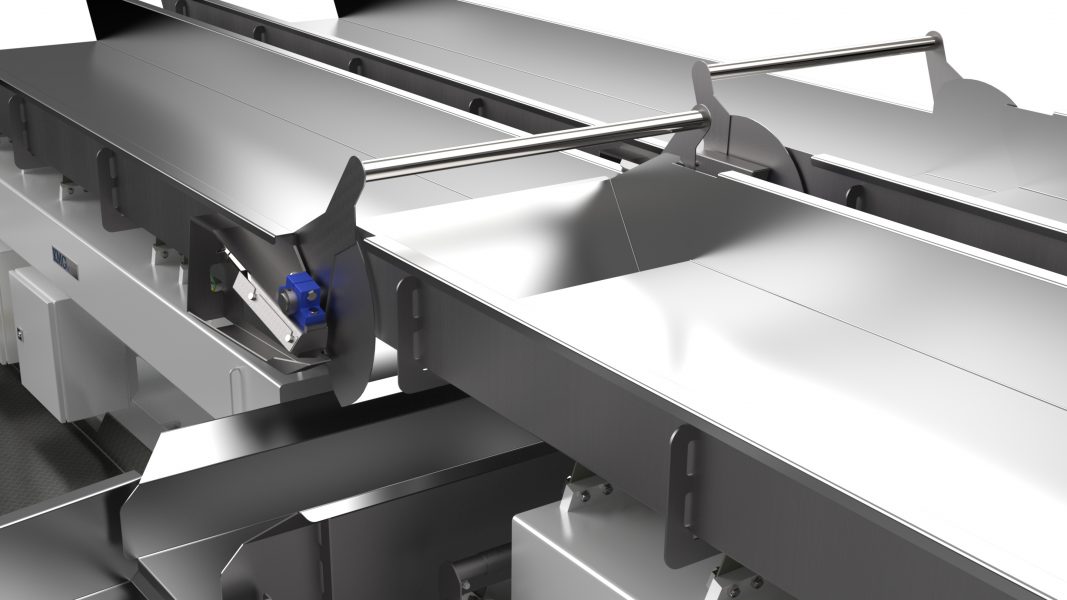

- Hygienic Design: Maintaining hygiene standards is a priority. These systems are constructed with hygiene in mind, aligning with industry requirements.

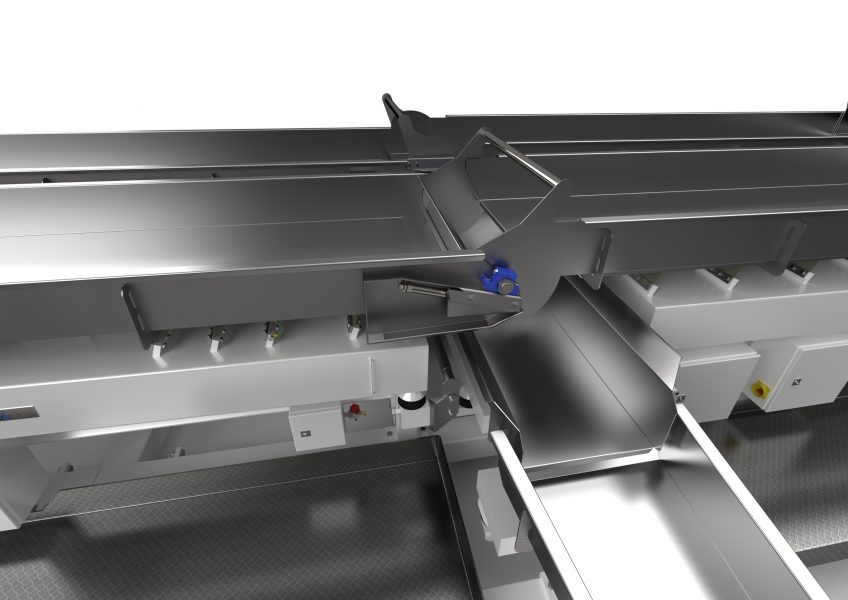

- Utilising KMG Vibratory Conveyors: The KMG vibratory conveyor serves as the foundation for these systems, contributing to their robust and reliable operation.

Food Vibratory Conveying Systems

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

Features

- Ensures maximum packing capability

- Systems programmed and tested at KMG

- Used with a variety of snack foods

- Eliminates the need for off line storage hoppers

- Hygienic

- Uses the KMG vibratory conveyor as the main building block

Discretely positioned photo-electric cells control the depth of product in the conveying system. KMG automation logic together with the modular nature of our systems ensures the demands of process are fully met by packing. Widely used in the snack food industry where multiple outlets to packing must be satisfied at all times, systems with KMG in line storage have eliminated the need for offline storage hoppers which are difficult and time consuming to clean.

See where else we use the In Line Storage Machine

Food Vibratory Conveying Systems with the In Line Storage

Distribution Systems

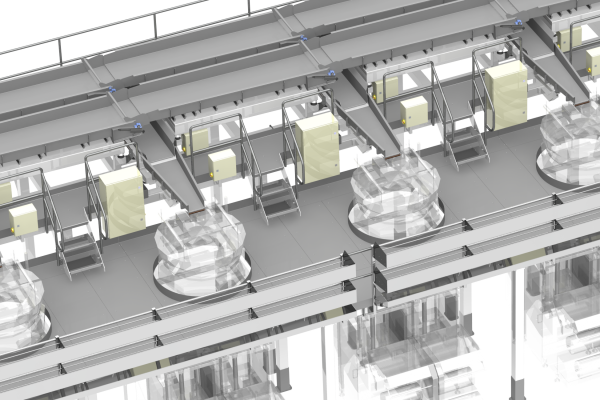

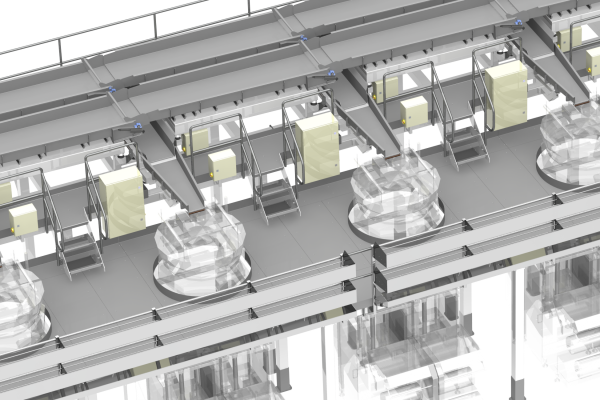

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems