- Conveying Fragile Product: The KMG AutoGlide® excels at handling fragile products with care and precision. It is an ideal solution for industries where product integrity is paramount.

- Long Straight Runs with Limited Space: This conveyor is designed to navigate long straight runs, making it a perfect choice when space for multiple machine supports or equipment is limited.

- Storage or Conditioning: The AutoGlide® can be employed for storage or conditioning purposes. By running the drive at a slower speed, it effectively conditions products, ensuring they are in the desired state for further processing.

- Multi-Gated Overhead Storveyor Feeds: It’s a versatile solution for industries that require multi-gated overhead storveyor feeds.

- Transfer Conveyors with Proportioning Feed: The AutoGlide® is also suitable for transfer conveyors with proportioning feed requirements, making it adaptable to various scenarios.

Food Vibratory Conveying Systems

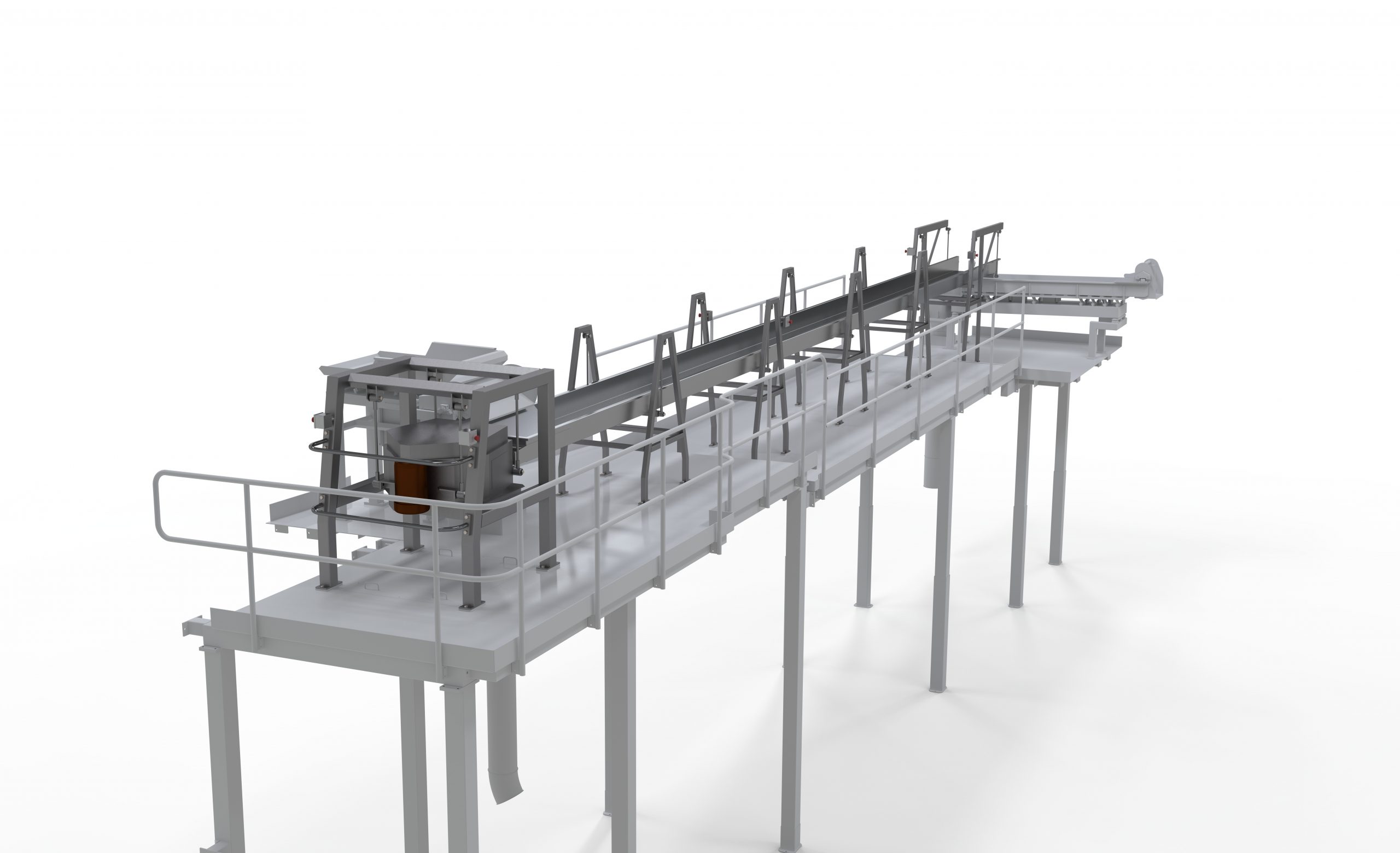

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

Features

- Conveying fragile product.

- Long straight runs with limited space for multiple machine supports or equipment.

- Storage or conditioning of a product by running the drive at a slower speed.

- Multi gated overhead storveyor feeds

- Transfer Conveyors with proportioning feed

The KMG AutoGlide® is a versatile and adaptable solution with a wide range of options to meet specific application requirements. It offers flexibility in conveyor lengths and widths, catering to the diverse needs of various industries. The conveyor pans are constructed from sanitary stainless steel, and a range of screens, coatings, and surface finishes are available to suit different product requirements. You have the flexibility to choose between floor-mounted or ceiling-hung installations, depending on the layout of your facility. Sanitary frame designs are available in satin-finished stainless steel or white food-grade enamel-coated carbon steel. The AutoGlide® is equipped with single or multiple gates for bottom discharge. The drop height during product transfer is minimal, ensuring product integrity is preserved during conveyance. You can adjust the conveying speed if variable speed is required for your application, adding an extra layer of adaptability. One key aspect to highlight is that the KMG AutoGlide® is a complementary solution to the KMG Vibratory conveyor, which serves as the building block for most systems. However, there are applications where horizontal motion conveyors are more suitable, such as for product conditioning, product storage, or transferring products over long straight runs. For example, you can employ the AutoGlide® to transport products across your factory to different processing or packaging areas efficiently. The AutoGlide® is equipped with a powerful oscillating drive that can convey over 3,000kg/hr of product across distances of up to 30 meters. This impressive capability allows you to enhance your existing key process equipment with flexibility and efficiency. When it comes to the drive unit, you have multiple options. The drive unit can be located over or under the conveying trough, based on your space constraints and application requirements. KMG offers three different drive sizes, which can be set in either a pull or push configuration. Rest assured, these drive units are incredibly robust and designed to provide reliable service for many years. KMG AutoGlide® (Horizontal Motion Conveyors) is vital to the evolution of product conveyance in the snack food processing and manufacturing industry. Its capacity for gentle handling, adaptability to various applications, and focus on product integrity make it a valuable asset for manufacturers. With its ability to cover long distances while preserving product quality, the AutoGlide® enhances the efficiency of your production processes, contributing to your industry's success.

See where else we use the KMG AutoGlide® (Horizontal Motion Conveyors) Machine

Food Vibratory Conveying Systems with the KMG AutoGlide® (Horizontal Motion Conveyors)

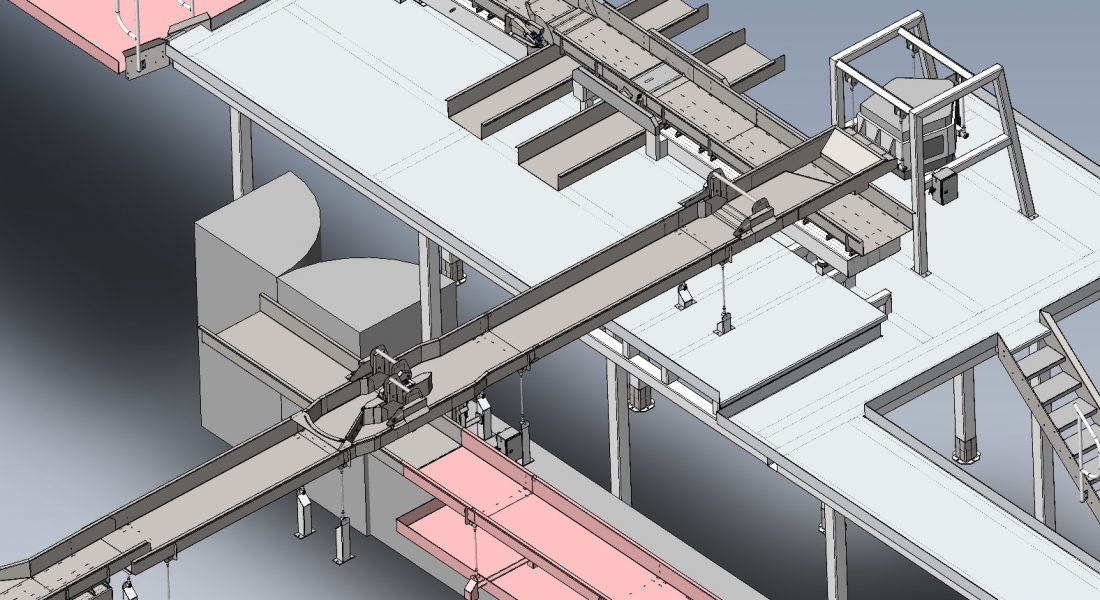

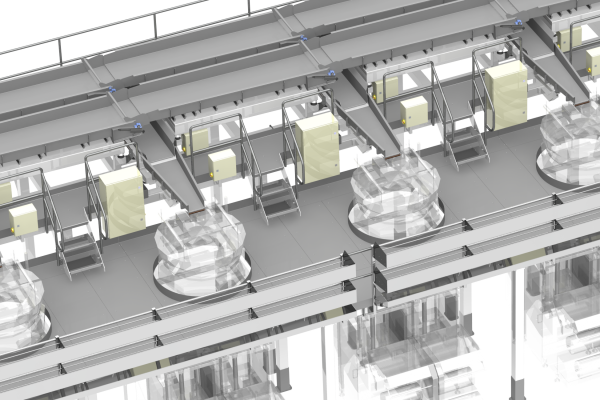

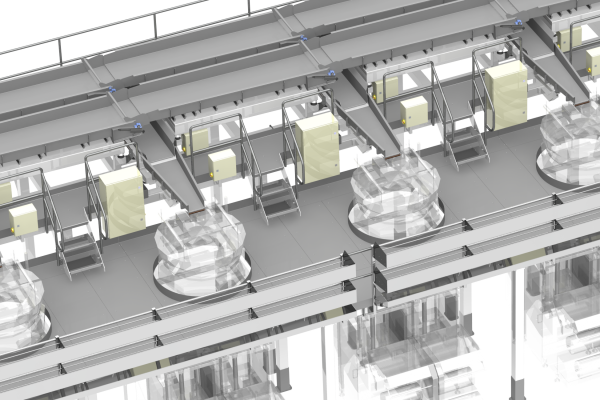

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems