Food Vibratory Conveying Systems

Process Preparation Area Machines

Pellet Bulk Handling

KMG pellet bulk handling systems provide a controlled and consistent feed of raw pellet products into the fryer.

Features

- Bulk handling of raw pellets to provide consistent feed to fryer

- Flow control conveyors to regulate flow

- Flow Weigher to provide mass flow measurement

- Consistent fryer feed important for oil temperature and consistent finished product

KMG Pellet Bulk Handling Systems provide a controlled and consistent feed of raw pellet products into the fryer. Our systems offer a seamless solution for the handling of raw pellets, ensuring a reliable and efficient production process.

To prevent bridging and maintain a steady flow of raw pellets, our systems feature a large hopper with an adjustable gate on the discharge. To regulate the flow of raw pellets, our systems include flow control conveyors. These conveyors regulate the flow of the product into the fryer.

Another component of our system is the patented KMG Flow Weigher. This innovative technology measures the mass flow of pellets, ensuring that the actual feed rate consistently matches the set point. This real-time measurement allows for precise control and adjustment.

See where else we use the Pellet Bulk Handling Machine

Process Preparation Area Machines with the Pellet Bulk Handling

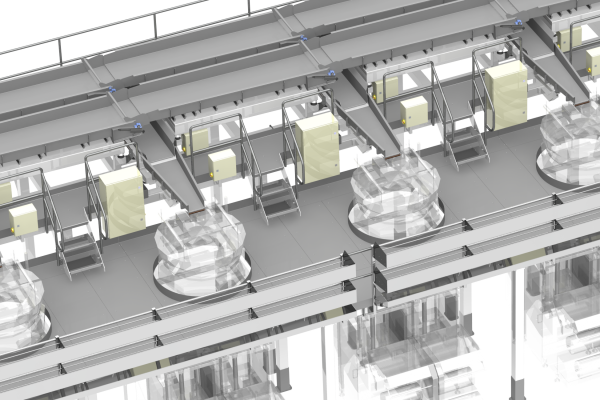

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines

Distribution Systems

KMG Distribution Conveyors are grouped into modules to form a distribution system that transports & distributes friable materials to any number of packaging stations. Our distribution conveyors are widely used in the snack food, breakfast cereal, petfood and confectionery sectors. The conveyors are the most hygienic and provide the highest throughput in the industry.

Distribution Systems

Process Preparation Area Machines

Using powerful out of balance mechanically driven vibratory conveyors KMG have successfully delivered a variety of products to and from various frying, drying, baking, toasting and freezing environments.

Process Preparation Area Machines