What Really Determines Long-Term Performance

When specifying food grade conveyor systems, many decisions are driven by compliance requirements and short term project needs. While meeting hygiene and safety standards is essential, long term performance depends on a wider set of design and engineering factors. The way a conveyor system is specified, built, and integrated into the production line has a direct impact on reliability, efficiency, and total cost of ownership over its working life.

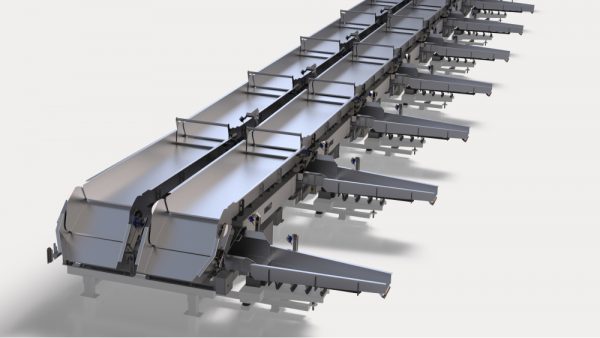

Design Quality Drives Reliability Over Time

One of the biggest factors in long term performance is the quality of the original system design. Conveyors that are designed specifically around the product characteristics, flow rates, and production environment tend to perform more consistently than generic solutions. Considerations such as product behaviour, transfer points, incline angles, and discharge control all influence how reliably a system operates over extended periods.

Poorly matched designs can lead to blockages, inconsistent flow, and increased mechanical wear, all of which reduce uptime and increase maintenance demands.

Material Selection Affects Durability and Maintenance

Food grade conveyors are exposed to frequent cleaning, moisture, temperature changes, and abrasive materials. The choice of materials, particularly frame construction, fixings, bearings, and contact surfaces, plays a major role in how well a system holds up over time. Robust stainless steel construction, appropriate surface finishes, and proven mechanical components help extend equipment life and reduce the need for unplanned intervention.

Systems designed with durability in mind are less likely to suffer from corrosion, premature wear, or structural fatigue.

Ease of Access Supports Consistent Performance

Long term performance is closely linked to how easy a conveyor system is to inspect, clean, and maintain. Designs that allow clear access to key components make routine servicing quicker and more effective. This reduces downtime and helps ensure the system continues to operate as intended throughout its lifespan.

Difficult access often leads to deferred maintenance, which can gradually impact performance and reliability.

Integration with the Wider Production Line Matters

A food grade conveyor does not operate in isolation. Its performance is influenced by how well it integrates with upstream and downstream equipment such as processing, seasoning, weighing, and packaging systems. Smooth transitions, stable feed control, and consistent discharge all contribute to overall line stability.

Conveyors that are engineered as part of a complete system are more likely to deliver predictable, long term results.

Why Experience Makes a Difference

Long term performance is rarely achieved by chance. Working with an experienced food conveyor manufacturer ensures systems are designed with a full understanding of operational demands and future production requirements. By focusing on engineering quality, durability, and integration from the outset, food grade conveyor systems can deliver reliable performance, reduced downtime, and consistent results year after year.