In snack food manufacturing, maintaining product quality from processing to packaging is a constant challenge. One of the most critical, yet often overlooked, contributors to this is conveyor design. Vibratory conveyors, in particular, play a key role in handling fragile, coated, or lightweight snacks, and their design can directly impact the consistency, hygiene, and appearance of the final product.

Vibratory conveyors are ideal for addressing this issue because they move products using a smooth, controlled vibration rather than belts or rollers. When properly designed, they offer a gentle motion that reduces impact and minimises the risk of product breakage. This helps to preserve shape and texture, which is essential for maintaining the visual appeal and eating experience consumers expect.

Product quality is also tied to flavour consistency. Uneven distribution of seasoning or coatings can result in a product that tastes different from one bite to the next. A well-designed vibratory conveyor contributes to uniform coverage by ensuring a consistent curtain of product passes under or through seasoning equipment.

By controlling amplitude, frequency, and tray geometry, vibratory systems can maintain a steady product flow, ensuring seasoning systems perform at their best. This is especially important in on-machine seasoning setups, where the product passes directly from the seasoning system onto the weigher bagmaker.

In food production, hygiene is non-negotiable. Conveyor design should always make cleaning easy, minimise contamination risk, and support compliance with food safety standards.

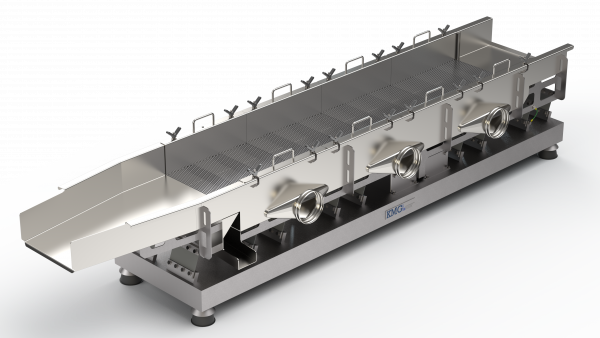

A good vibratory conveyor will be made from food-grade stainless steel, with smooth surfaces, minimal crevices, and a design that allows for fast access and washdown. This helps manufacturers reduce downtime for cleaning and maintain high hygiene levels throughout their line. Some systems also incorporate clean-in-place (CIP) features, allowing for more efficient sanitation routines without full disassembly.

Vibratory conveyors, especially electromagnetic ones, use less energy than many traditional mechanical systems. Because there are fewer moving parts, they also tend to require less maintenance and are less prone to wear. This means fewer breakdowns, lower running costs, and more reliable performance over time, all of which contribute to consistent product output and improved operational efficiency.

Not every snack is the same. Whether you’re handling seasoned crisps, sticky-coated nuts, or mixed snack blends, the conveyor must be designed to suit the specific product characteristics. Tray angles, feed rates, discharge points, and vibration settings can all be customised to ensure optimum performance.

By working with experienced equipment manufacturers, food producers can ensure their vibratory conveyors are matched to their exact needs, helping to protect product quality, reduce waste, and support consistent production.