Snack production has become increasingly sophisticated, and the development of on-machine seasoning (OMS) has played a major role in this progress. By applying flavouring directly at the final stages of the production line, manufacturers have gained greater control over flavour consistency, improved efficiency, and reduced waste, all while meeting the high expectations of today’s consumers.

Seasoning systems used to be positioned earlier in the manufacturing process, which often led to flavour loss, uneven coverage, and difficulty maintaining hygiene standards. Seasoning drums and feeders were typically located away from packaging areas, requiring additional conveying and handling. This increased the chance of breakage, cross-contamination, and excess use of ingredients.

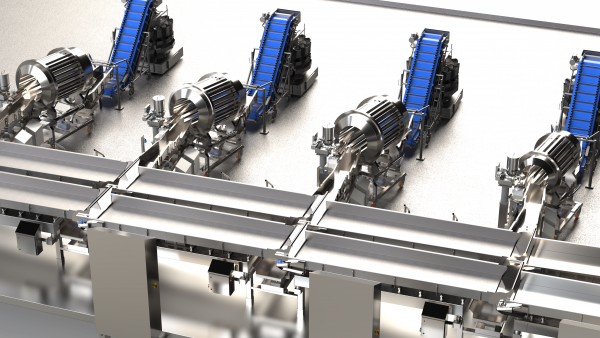

OMS changed that model. By bringing seasoning application directly above the packaging station, producers can apply flavours precisely as the product is about to be packed. This minimises handling, reduces residue build-up on conveyors, and allows more consistent coating of each batch.

Today’s OMS systems are far more advanced than early versions. Key components like flow weighers and vibratory scarfed-edge feeders work together to measure product flow in real time and adjust seasoning application automatically. As a result, even if the production rate fluctuates, the system can maintain accurate flavour dosing without manual adjustment.

This flexibility is particularly useful for manufacturers running a variety of snack products, from extruded curls to potato crisps, all requiring different coating profiles. Whether working with dry powders, oil-based flavourings, or slurry mixtures, OMS equipment is engineered to handle a range of seasoning types with precision.

Hygiene has always been a top priority in snack food production, and on machine seasoning helps meet this challenge. Most systems are built from food-grade stainless steel, with smooth, easy-to-clean surfaces that reduce the risk of cross-contamination. Automated washdown routines allow for faster cleaning between flavour changeovers, limiting downtime while maintaining compliance with food safety regulations.

Beyond hygiene, OMS contributes to sustainability. Because flavour is applied with precision and in sync with product flow, there is significantly less ingredient waste. Over time, this reduces operating costs and supports environmental goals.

OMS is no longer just a smart addition to a snack line, it’s becoming standard practice for manufacturers looking to maintain quality while scaling up production. The ability to combine real-time flow measurement, accurate dosing, and minimal handling means that snack producers can consistently meet both regulatory requirements and consumer expectations.

As global demand for flavoured snack products continues to rise, so does the need for efficient, hygienic, and responsive seasoning technology. On machine seasoning offers a proven solution that balances product quality with operational efficiency, making it an essential part of any modern snack food manufacturing setup.