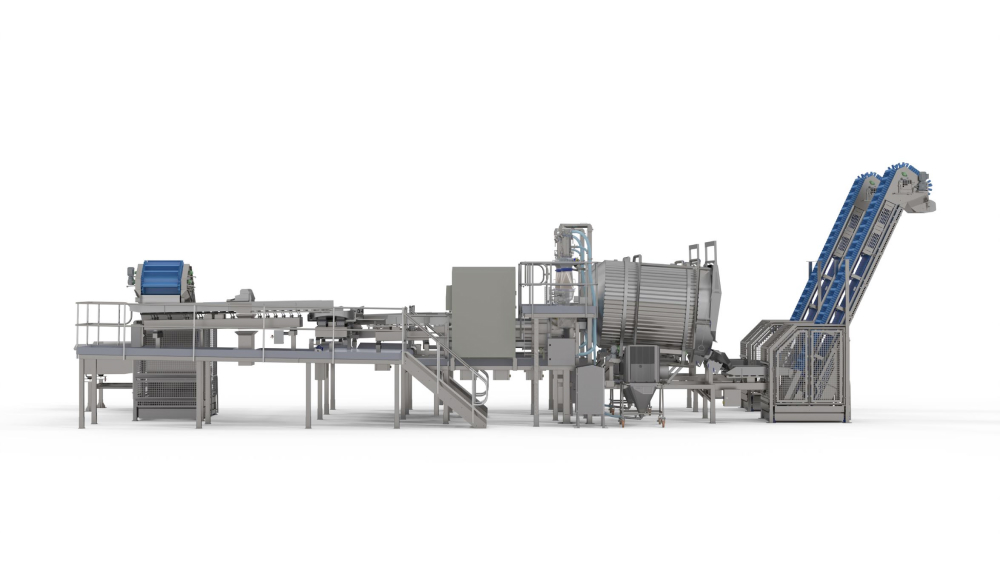

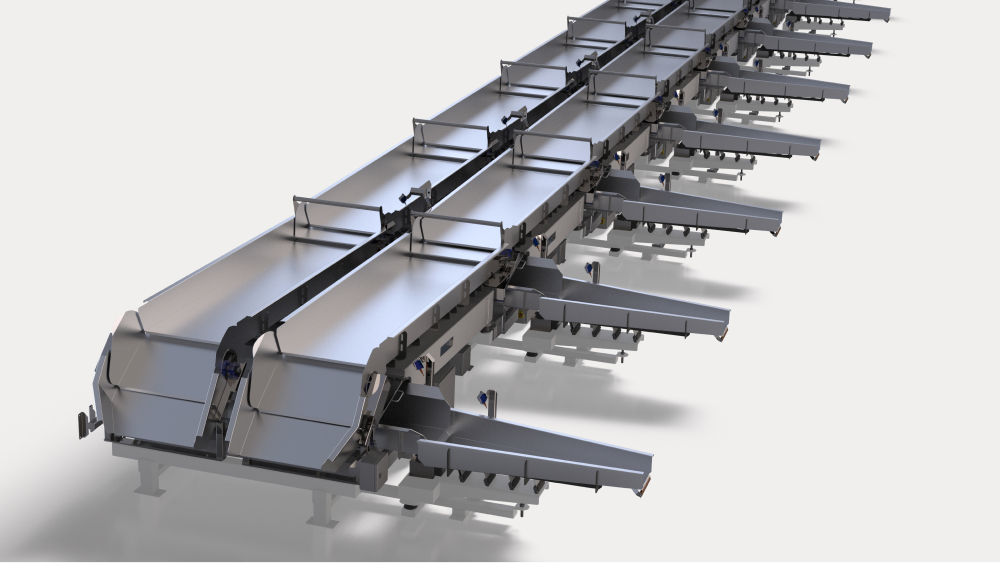

- Constructed to withstand the challenges of high-demand manufacturing environments. Their robust construction ensures durability and longevity, even when subjected to constant operation.

- User-Friendly: KMG’s Case Tapers are designed with the user in mind, offering intuitive controls and a straightforward setup process.

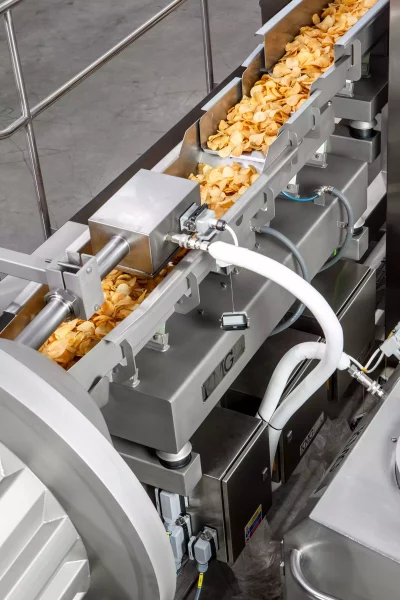

- Efficient: By automating the case sealing process, they eliminate the need for manual operation, freeing up your team to focus on more critical tasks within the production process, thus increasing overall efficiency.

- Small Footprint: Our Case Tapers are built with a compact footprint, ensuring they can seamlessly integrate into your existing production line.

- Hot Melt or Adhesive Tape: Case Tapers can accommodate both hot melt and adhesive tape, allowing you to choose the sealing method that best suits your specific requirements.