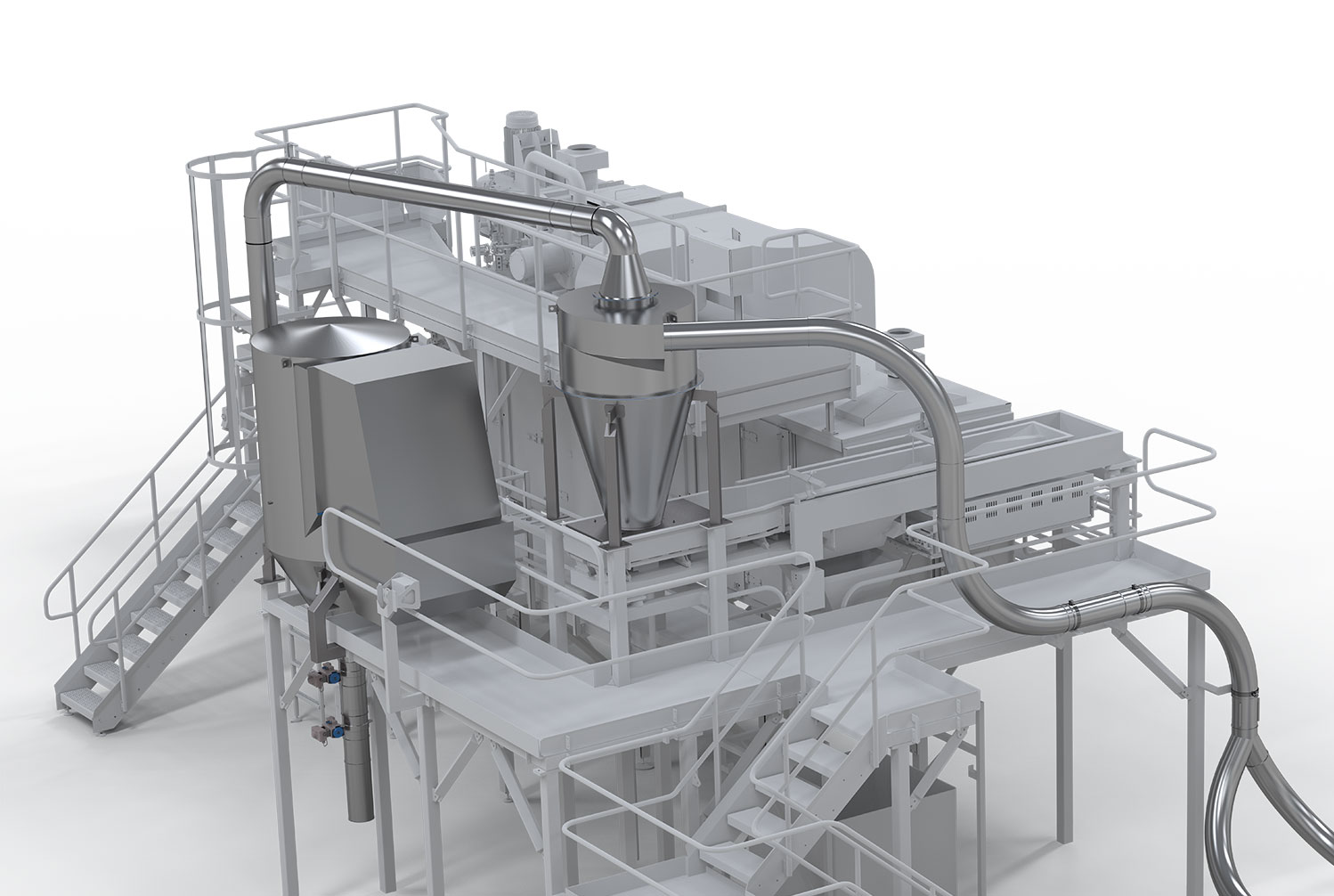

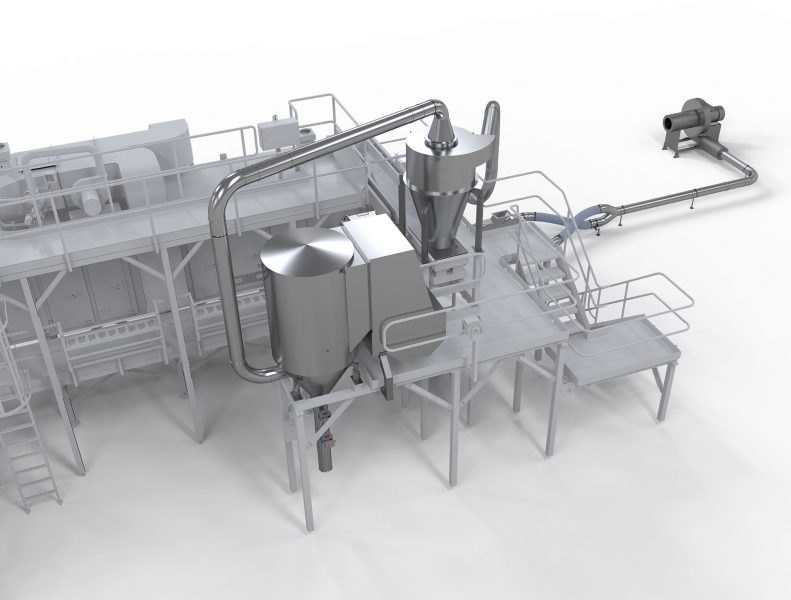

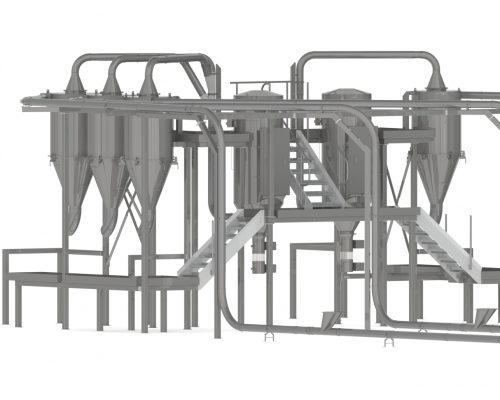

KMG medium phase pneumatic conveying systems transfer bulk materials through an enclosed conveying pipeline. The system provides transportation of product and removal of dust particles. It consists of a variable speed fan, venturi, cyclone and reverse jet cleaned baghouse.

A flow of air is initiated at the fan. The air travels through the venturi with high pressure causing a vacuum above the venturi. The venturi draws product from the process into the travelling air, whilst maintaining a high pressure gradient in the forward direction of travel.

Any dust particles generated by the process will be drawn out of the cyclone by a secondary air stream that is created by a negative pressure gradient from the baghouse. Dust particles have a lower inertia than the product and will not travel around the wall of the cyclone. The particles will travel close to the centre of the cyclone and will be drawn out through the Cyclone’s outlet thimble to the baghouse.

Specific to the food industry KMG air conveying systems are individually tailored to our customers requirements and are manufactured from stainless steel for all food contact parts. Pipe work, cyclones and filters are also all stainless steel construction.

Focussed on the snack food sector our air conveying systems are commonly used in extrusion lines for transporting raw pellets from extruders to bulk or box off stations. They are also commonly used for transporting extruded snacks immediately from the cutter head of the extruder to the next process, usually a drier.