Special Purpose

KMG specialise in the design and manufacture of bespoke machinery to customers who have a problem that is not catered for by the ranges of standard machinery already on the market. Our level of expertise is primarily in product flavouring, blending, screening and packaging applications.

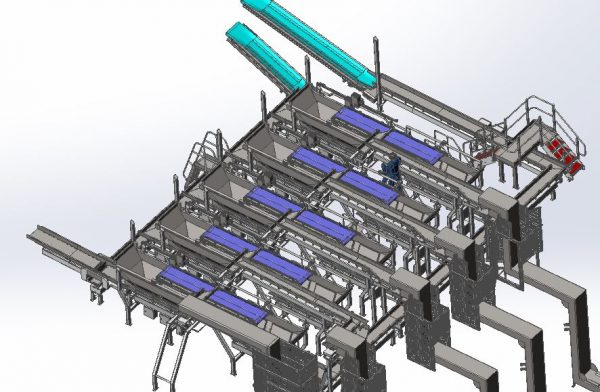

With a team of over 30 design engineers KMG has the capability and experience to design and manufacture a solution to your problem. On hand are the latest in 3D modelling and FEA analysis, laser cutting and laser welding techniques. Our motives are to increase cost efficiency and time savings by automating processes.

Contact Us

Features

- Cooling conveyors

- Screening and grading vibratory conveyors

- Bespoke seasoning storage and transportation solutions

- Bespoke automation

- Inspection vibratory conveyors

- Laning and spreading vibratory conveyors

- Mobile vibratory conveyors

Special Purpose Machines

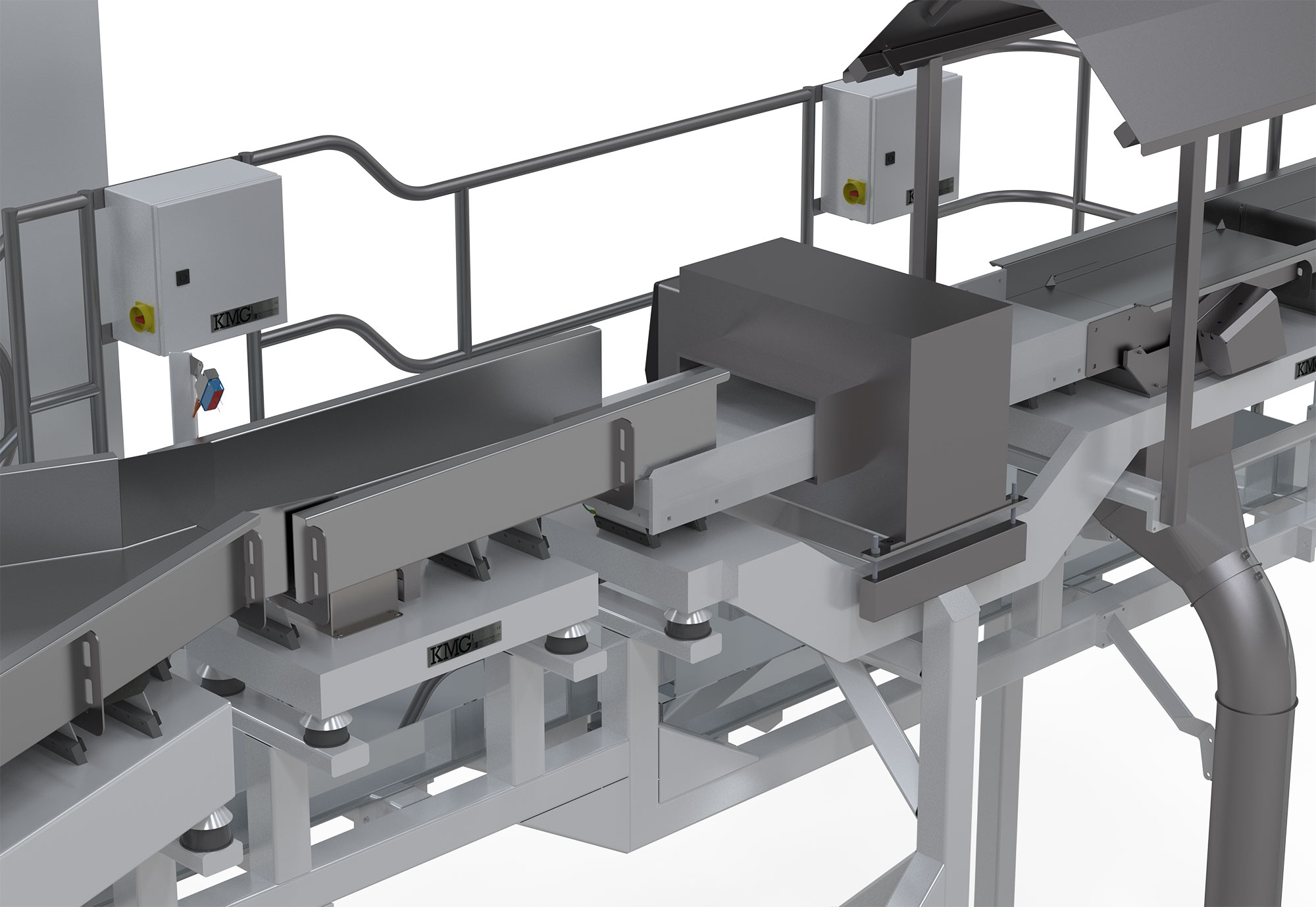

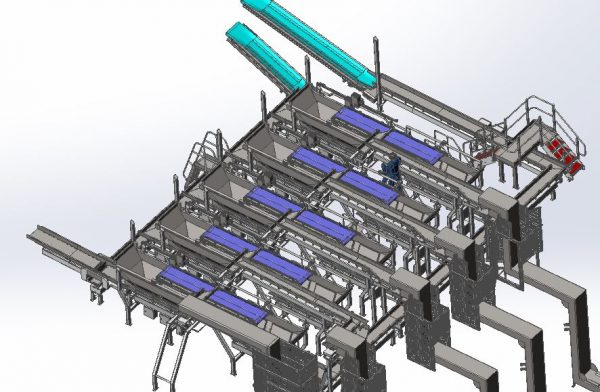

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Inspection Vibratory Conveyor

Inspection Vibratory Conveyors enable manual inspection of conveyed product, giving an opportunity to remove any substandard product and maintain quality standards. This has a lower investment cost than expensive mechanical or optical sorting process equipment.

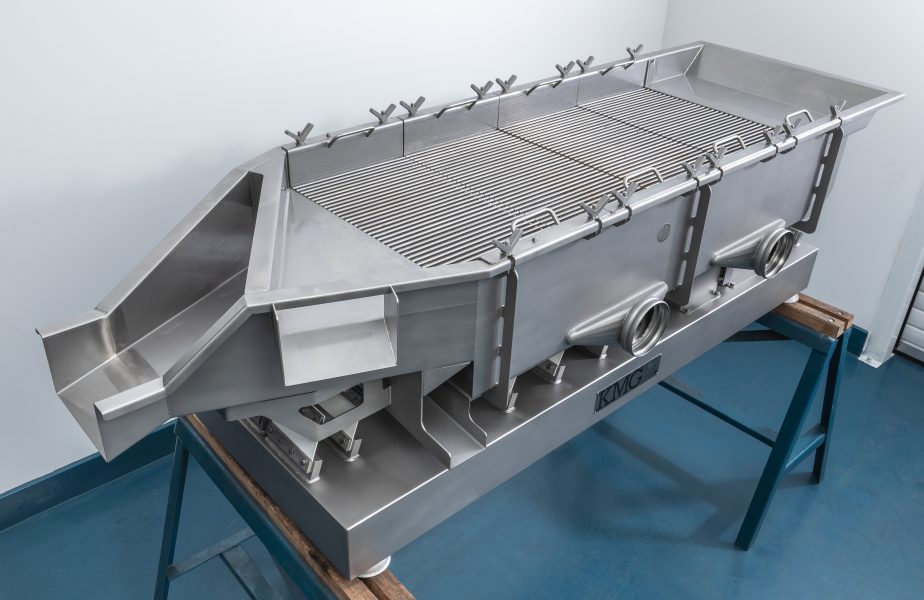

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

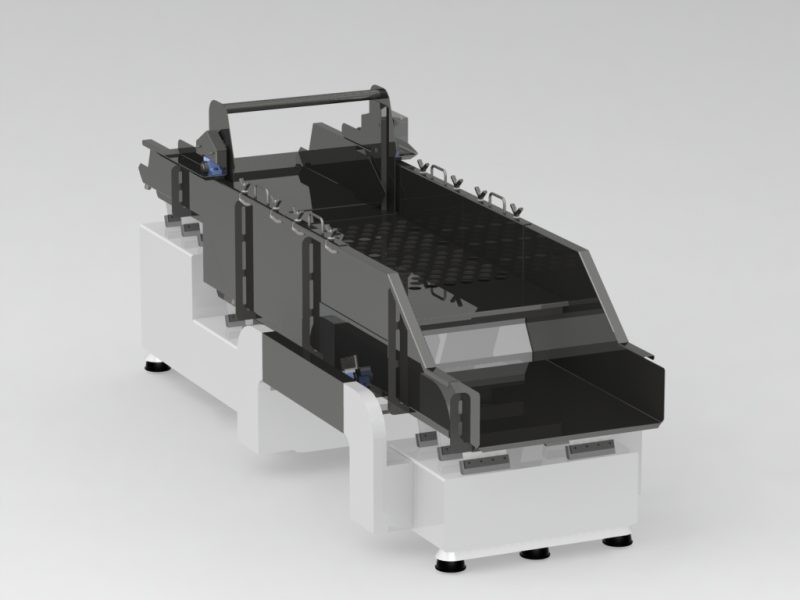

Grading Vibratory Conveyor

Grading vibratory conveyors are used to safely and hygienically separate product by size. As part of your manufacturing process it can be desirable to grade and separate undersize and oversize product. A KMG grading vibratory conveyor will be designed to use a suitable mesh or screen. This could be punched holes, bars, mesh or proprietary screens. A machine like this will always be designed and built to your specification, using our decades of grading experience.

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Product Blending

KMG understands the importance of accurate mixing ratios, gentle product handling and achieving consistent and precise blends. With our advanced blending systems, we offer professionals in the industry the ability to combine multiple product streams to create homogenous mixes. Whether you need to feed a packaging machine or a seasoning loop, our blending systems deliver exceptional results, ensuring the perfect blend every time.

Product Blending

Inspection Vibratory Conveyor

Inspection Vibratory Conveyors enable manual inspection of conveyed product, giving an opportunity to remove any substandard product and maintain quality standards. This has a lower investment cost than expensive mechanical or optical sorting process equipment.

Inspection Vibratory Conveyor

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Cooling Vibratory Conveyors

Grading Vibratory Conveyor

Grading vibratory conveyors are used to safely and hygienically separate product by size. As part of your manufacturing process it can be desirable to grade and separate undersize and oversize product. A KMG grading vibratory conveyor will be designed to use a suitable mesh or screen. This could be punched holes, bars, mesh or proprietary screens. A machine like this will always be designed and built to your specification, using our decades of grading experience.

Grading Vibratory Conveyor

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.

Mobile Vibratory Conveyors

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Laning Vibratory Conveyor

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Spigot Discharge Vibratory Conveyor

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Tubular Vibratory Conveyors

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product. These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Spreader Vibratory Conveyor