Seasoning Systems

Repeatability and accuracy are essential to good product seasoning and KMG has for many years been at the forefront of seasoning system developments. Whether you wish to season in the kitchen at ground level or directly above the packing system, KMG has seasoning systems to suit all requirements. At KMG we understand the importance of accurate, repeatable seasoning delivery and our seasoning systems are designed to be robust and reliable.

Overview

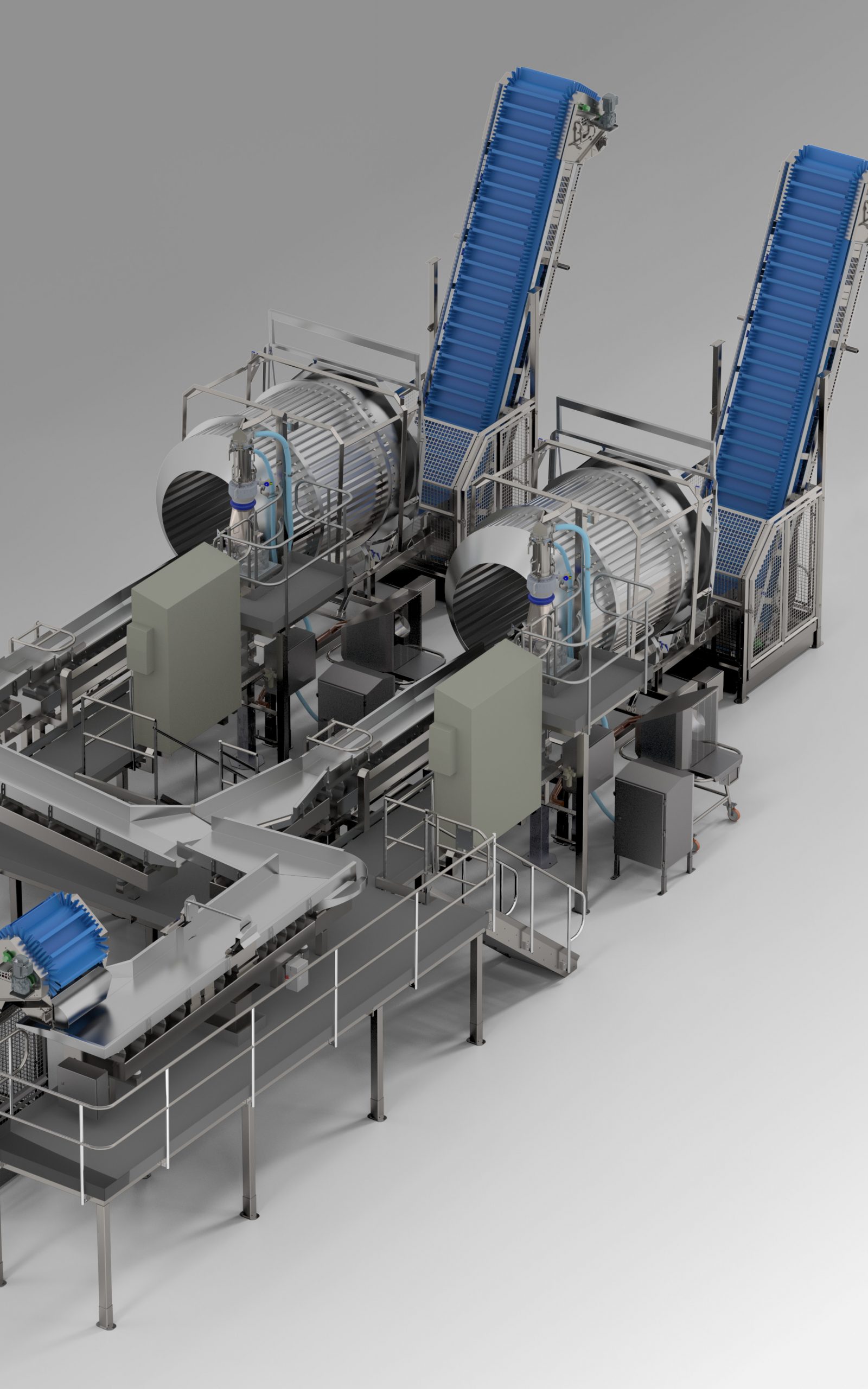

On-machine seasoning (OMS) was pioneered by KMG more than 40 years ago, and we have refined and developed it over the years to ensure that we remain the seasoning specialists. We have designed and built many seasoning systems to feed one or more seasoning drums directly above the packaging system. Most snack food industry leaders have benefited from KMG kitchen seasoning systems to drive production and profits. We keep costs down by delivering accurately metered seasoning using equipment which is designed to be robust and reliable with ultra low running costs.

Our stainless-steel seasoning coating drums are uniquely designed to ensure even and consistent coating. They feature multiple lift flights, fully welded hygienic construction, with speed and angle adjustment as required. Our expertise allows us to design the lift flights to perfectly suit your base product characteristics. Whether your are applying dry seasoning, oil and dry seasoning or slurry, we will design the perfect seasoning coating drum for your application.

In addition, using proprietary software, KMG has developed a unique Loss in Weight system giving our seasoning systems unparalleled performance and unsurpassed user-friendly features. Have a look at our Loss in Weight page to learn more about how we switch from gravimetric to volumetric dosing.

Features

- Industry leading process capability

- Accurate, repeatable, stable process control

- Recipe based

- Compatible with KMG Liquid Spray Unit, Vacuum Lift System

- Proportional gravimetric measurement of product and seasoning flow

Seasoning Systems Machines

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Vacuum Lift (VLS)

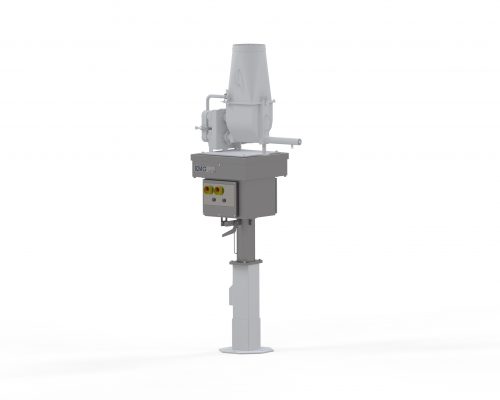

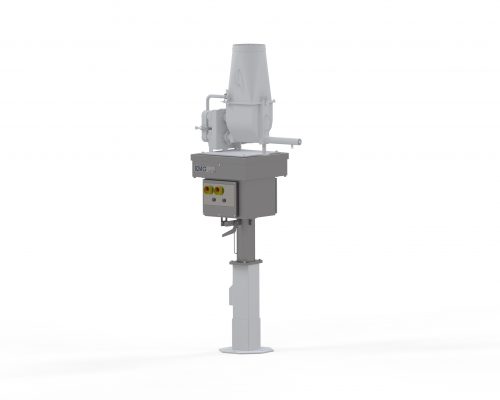

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Liquid Spray Unit

The KMG Liquid Spray Unit (LSU) demonstrates our focus on good design combined with excellent performance. The KMG LSU operates without the use of compressed air which means no oil mist and sets a new standard in levels of accuracy.

Liquid Spray Unit

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Cooling Vibratory Conveyors

Cooling vibratory conveyors are designed to cool product as it passes over the screen. The vibratory conveyor pictured has spigots incorporated in order to provide a flow of cooled air over the product. Other designs incorporate fans or vents. The number of spigots would depend on the size of the trough, volume of product and the degree of cooling required.

Cooling Vibratory Conveyors