Kitchen Dry Seasoning

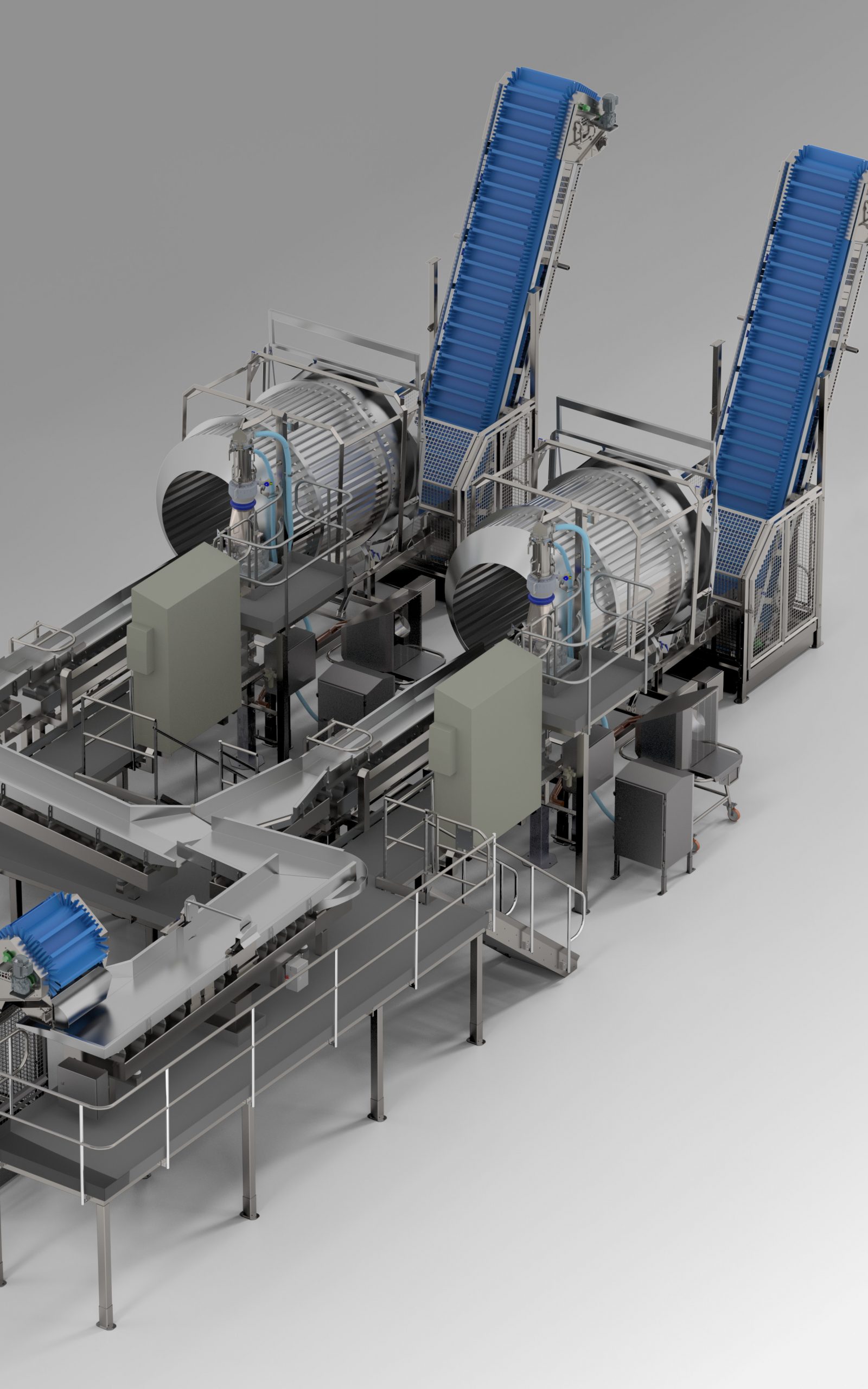

KMG Kitchen dry seasoning systems are designed to surpass process throughput and seasoning application requirements and tailored to your factory layout. Typically one to three drums are fed by proportioning systems from the main process.

Focusing on safety and hygienic design principles, there are many options available; including split base product proportioning, from one process to multiple flavour loops, wet and dry seasoning application (or a combination of both); plus, bulk handling of powdered seasonings.

The KMG kitchen dry seasoning system uses combinations of equipment from our industry leading portfolio, the base product is seasoned at ground level and elevated to our distribution system for gentle transfer to packing.

Contact Us

Features

- Ranges from 150kg/hr. to 3,000kg/hr. across various drum and system sizes.

- Automatic adjustment of proportioning system, feeds respective drum based on distribution lane capacity (KMG distribution only)

- Base product in-flight weight measurement, using KMG’s patented Flow Weigher, combined with Volumetric or Gravimetric (Loss-in-weight) seasoning application.

- Seasoning Flavour application to include wet, dry or combination of both.

- Choice of Siemens or Allen Bradley controls, with the option of system integration including Wonderware and SCADA.

- Suitable for fried, baked, extruded, popped or pellet type snacks.

- Low Energy/Low Maintenance/Low Running Costs!

Kitchen Dry Seasoning Machines

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

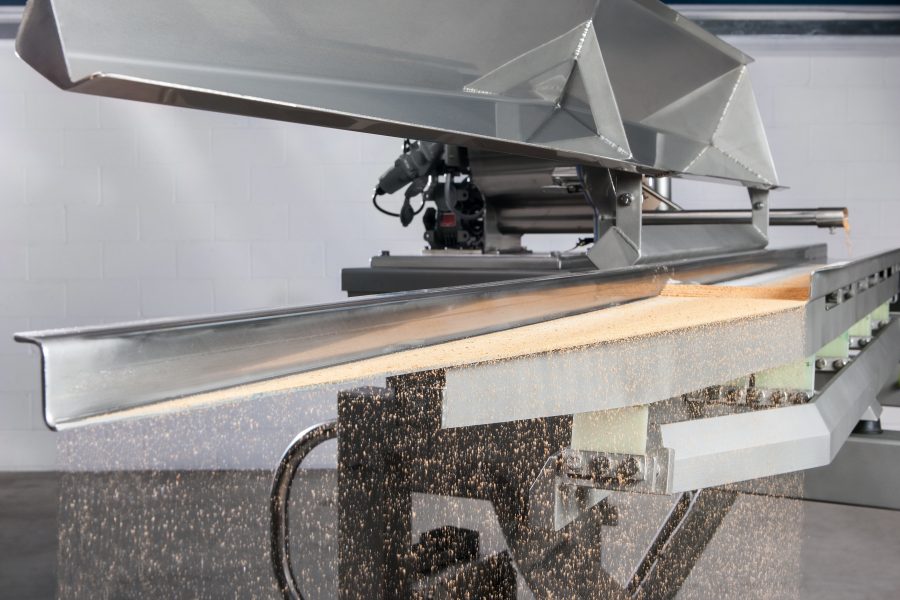

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

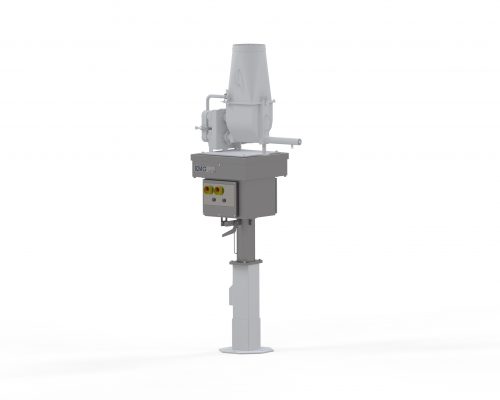

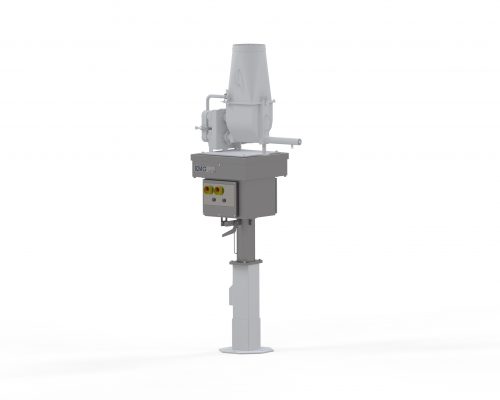

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Proportioning Control Vibratory Conveyor

The control of feed from process to multiple seasoning or packing lines using a single vibratory conveyor with proportioning split from 0-100%.

Proportioning Control Vibratory Conveyor

FlowWeigher™

The KMG FlowWeigher™, a vibratory flow rate measuring system, is engineered to address precision and accuracy to ensure product quality and optimise manufacturing processes with ground-breaking technology. It stands out as the only system that integrates a load cell directly beneath the vibratory tray that holds the product. This patented innovation enables the real-time measurement of the flow rate of even very light materials with exceptional accuracy.

FlowWeigher™

KMG Loss in Weight (LIW)

KMG Loss in Weight (LIW) as part of a seasoning application system ensures the correct amount of seasoning is always applied.

KMG Loss in Weight (LIW)

Powder Dosing Unit

Our Patented Powder Dosing Unit comes with all the features that you would expect from KMG. Its designed to be robust, reliable, easy to use and hygienic. Suitable for a wide range of seasonings, the KMG Powder Dosing Unit is designed with customer product, process and expectations in mind. It works seamlessly with our Loss in Weight, patented FlowWeigher and Vacuum Lift system to form the backbone of our world class seasoning system.

Powder Dosing Unit

Flavour Feed Vibratory Conveyor

The Flavour Feed Vibratory Conveyor, also known as the scarf feeder, is an extremely important component in the realm of snack food production. This unassuming yet indispensable machine plays a critical role in conveying seasoning or salt powder into the flavour drum, ensuring consistent and precise flavour application. This machine efficiently contributes to the production of perfectly seasoned snacks and it’s exactly what you need to make your snacks taste perfect.

Flavour Feed Vibratory Conveyor

Flavour Drum

Flavour- one crucial aspect of the complex world of snack food production. It's no secret that the seasoning process is key to creating products that tantalise taste buds. From potato chips to extruded snacks and tortilla chips, the KMG seasoning flavour drums are engineered with a singular focus: to elevate product quality and consistency through precise seasoning.

Flavour Drum

Flavour Vacuum Lift (VLS)

In the world of snack food manufacturing, precision isn't just an option; it's an absolute necessity. One vital yet often missed component that ensures this precision is the Flavour Vacuum Lift (VLS) by KMG. This remarkable piece of machinery is designed to convey batches of powders efficiently and hygienically within ducting, making it a cornerstone of snack food production.

Flavour Vacuum Lift (VLS)

Air Filtration Unit (AFU)

An often underestimated yet crucial component that plays a significant role in maintaining product quality and ensuring the well-being of employees is the Air Filtration Unit (AFU). Specifically engineered by KMG, the Air Filtration Unit (AFU) represents an indispensable dust containment system meticulously designed to operate seamlessly alongside a seasoning fill hopper or the KMG Vacuum Lift System (VLS) to ensure precision and hygiene.

Air Filtration Unit (AFU)

Smart Seasoning Validation

In the food manufacturing industry, ensuring the safety and quality of products is paramount, especially when it comes to allergen risks. Smart seasoning validation is a cutting-edge solution designed to make it easy for operators to load the correct seasoning and prevent operators from inadvertently filling a seasoning hopper with the wrong seasoning, thereby minimising the potential for allergen cross-contamination. KMG designed these features of smart seasoning validation, and fully recognise its crucial role in maintaining allergen control and safeguarding product integrity.

Smart Seasoning Validation