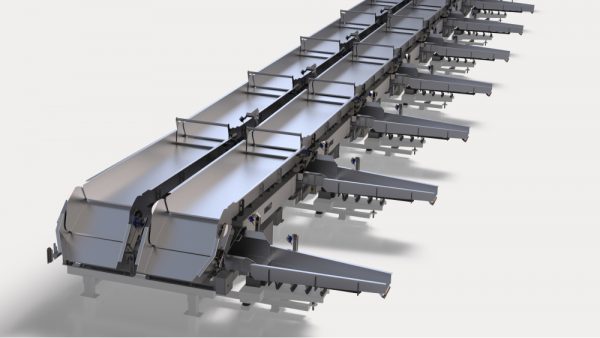

KMG Gated Vibratory Conveyors are a fundamental component of a sophisticated distribution system, engineered to transfer, divert, or reject products with unparalleled precision, thanks to its electro-pneumatically controlled gates. In this blog, we will delve into the impressive features and capabilities of KMG Gated Vibratory Conveyors.

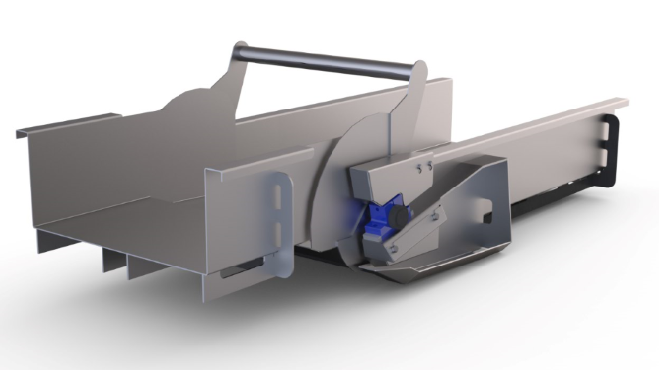

Precise Control with Balanced Gates

KMG Gated Conveyors transfer product from process to any number of packaging machines by integrating a simple pneumatically operated opening, that is integrated into the vibratory conveyor. The gates can be positioned “in-trough” or “end of trough” dependent upon requirements. Several can be installed in a row to create a distribution system typically used to deliver snacks and cereals to multiple weigher/bagmakers. At KMG we are always conscious of the need for good hygiene and operator safety. The balanced gates means that they are actuated with only the smallest pressure, causing them to move slowly and with minimal force. This makes them very safe and eliminates the need for guarding. They are easy to clean because there is no guarding, it’s a win-win.

Gated vibratory Conveyors: Modular Design for Adaptability

At KMG Systems, we understand that versatility is key to meeting diverse industry requirements. Our Gated Vibratory Conveyors boast a modular design, allowing for easy customisation and adaptation to various applications. The conveyor can be tailored to your specific needs – taking product characteristics and downstream packaging equipment into account and ensuring a seamless fit into your production line. Whether you are producing potato chips, popcorn, snacks, cereal or petfood, KMG will specify equipment to suit your needs. We can feed onto any combination of weigher/bagmakers and take account of downstream secondary packaging, for example ACPs.

Gentle Handling for Optimal Results

One of the standout features of KMG Gated Vibratory Conveyors is their use of controlled vibration technology. This innovative approach ensures a gentle and even transfer of conveyed product, while using ultra-low power. Our electro-magnetically driven Vibratory Conveyors use vibration at natural frequency making them completely safe, ultra-quiet and use less power than a 100W incandescent light bulb. We have optimized the power profile of our drives to provide the gentlest possible forward motion. At KMG we have the experience to design our Gated Vibratory Conveyors to suit the bulk density of the conveyed produce plus any special characteristics, whether it is dusty, friable, sticky, dense or brittle.

Low Lifetime Cost

At KMG we recognise that the cost of equipment is more than the initial capital outlay and it is important to us to keep the lifetime cost of Gated Vibratory Conveyors low. We design our machines to be robust and easy to maintain. One of the four pillars of the KMG design strategy is maintenance – we strive to ensure that our equipment runs with the minimal maintenance, and where it is required, we plan easy access. We fully expect our Gated Vibratory Conveyors to continue in operation for 30 years or more. Maintenance tasks can easily be carried out by your own in house team. We manufacture the majority of our components in house giving us unrivalled spares availability.

Advanced Control System for Seamless Integration

To empower businesses with real-time control and monitoring, the KMG Gated Vibratory Conveyors are controlled by our advanced automation software. Our intuitive interface enables operators to select appropriate recipes with ease. Engineers have access to adjust other key parameters. Real-time diagnostics facilitate proactive maintenance and troubleshooting, minimising disruptions to the production process. When we supply a distribution system we design and construct the electrical infrastructure, programs logic control and operator interfaces using in house developed philosophy.

Unmatched Material Flow Control

Industries that deal with multiple products or engage in batch processing understand the importance of accurate material segregation and metering. This is where the KMG Gated Vibratory Conveyors truly shine as a component of our distribution systems. By incorporating balanced gates along the run of conveyors, the system allows for precise regulation of material discharge. This level of control proves to be a game-changer, enabling businesses to achieve optimal product flow rates and boosting overall productivity.

Overall, the KMG Gated Vibratory Conveyor is a unique and innovative machine that allows snack manufacturers to achieve improved material handling and streamlined production processes. By embracing this solution, businesses can enhance their operational efficiency, achieve higher yields, and deliver products of consistent quality.