Gated Vibratory Conveyors

KMG Gated Vibratory Conveyors offer an innovative solution that delivers reliable and efficient product transfer, making them a cornerstone in various industries, from seasoning applications to packing processes, ensuring precision and control over the transfer of the product.

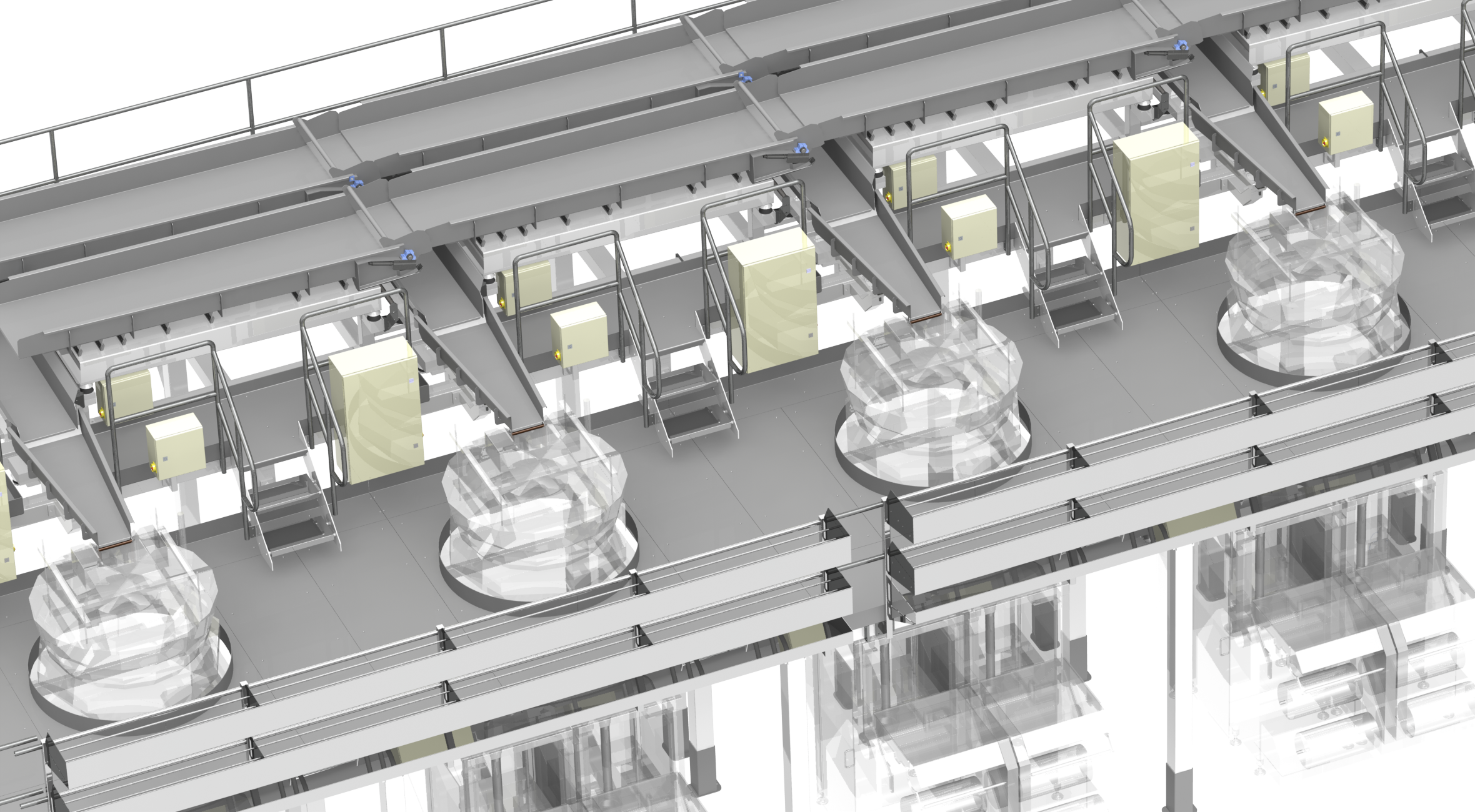

In Line Storage

In manufacturing, the ability to maintain a continuous and efficient production process is paramount. The introduction of KMG In-Line Storage systems revolutionises the management of processed products in the snack food industry. These systems not only ensure uninterrupted packing capabilities but also eliminate the need for offline storage hoppers.

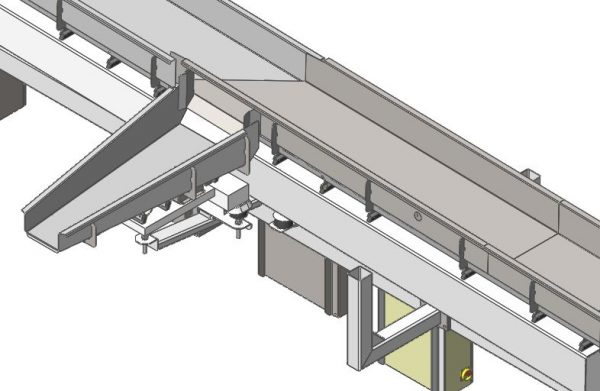

KMG Autoflow Plus

KMG introduces the patented Autoflow Plus, a gateless distribution system that minimises product drops and eliminates moving parts. This innovative system is a game-changer for the industry, offering a new level of control, efficiency and precise distribution./l

Storveyor

In industrial processes, maintaining a consistent and uninterrupted flow of products is essential to optimise productivity and minimise disruptions. The KMG Storveyor offers a reliable solution by accommodating a buffer of product between two processes, mitigating stoppages or surges. Professionals in various industries can leverage the Storveyor's capabilities to enhance efficiency and streamline their production processes.

KMG AutoGlide® (Horizontal Motion Conveyors)

The KMG AutoGlide®, also known as a horizontal motion conveyor, stands out as an innovative and gentle means of product conveyance which plays a pivotal role in ensuring the gentle and efficient movement of products. Let's delve into the world of the KMG AutoGlide® to explore its features and applications.

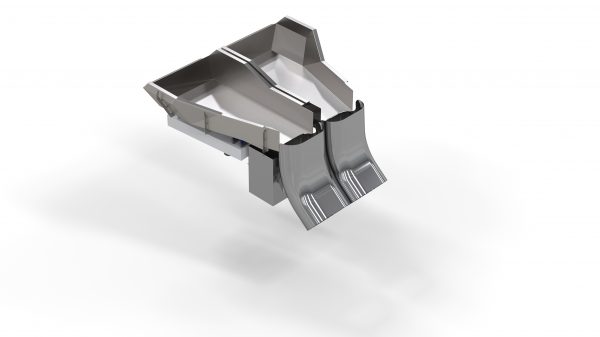

Servo Assisted Proportioning Chute

When it comes to proportioning product feed into multiple directions, space constraints can often pose a challenge. However, the KMG Proportioning Chute offers a solution that is both efficient and space-saving. In this blog post, we will explore the features and benefits of the Servo Assisted Proportioning Chute, highlighting its accurate servo-controlled rotation, easy cleaning and maintenance, inherent safety, and seamless product changeover capabilities.

KMG Drop Weigher

Managing waste is useful aspect of the process of snack production, and its accurate measurement is essential. KMG introduces the Drop Weigher, a solution that provides real-time and precise weight measurements for waste on food production lines. Let's explore this innovative system in detail.

Vibratory Conveyors

KMG Systems offer a range of hygienic vibratory conveyors which are designed to be ultra low energy, virtually silent in operation and easy to clean. We use our own electro-magnetic drive to transport and handle bulk materials including snacks, cereals and petfood. We design the conveyors to suit your needs, taking into account your factory environment and the base product characteristics.

Weigher Feed Vibratory Conveyor

KMG weigher feed vibratory conveyors are used to give manufacturers a controlled feed of product on to the multi-head weigher. KMG Systems design and manufacture weigher feed vibratory conveyors specifically for the food industry. With our 50 years of experience, we design our equipment to be hygienic, easy to clean and easy to maintain. We know that you will be operating to the highest hygiene standards and we take that into account with our designs.

Breakfast Cereal Vibratory conveyors

From process to packaging, cereals need to be conveyed with care. At KMG we specialise in bespoke applications and with our decades of experience, we understand the specialised requirements of cereal factories.

Spigot Discharge Vibratory Conveyor

Spigot discharge vibratory conveyors are generally used to provide an even feed onto a multi head weigher; or within a covered system, to provide a hermetically sealed feed to a downstream conveyor or process. They are ideal if your product is particularly free flowing, for example chocolate flake, pellets, lentils, or coffee beans. We have even used them for larger products such sausages.

Tubular Vibratory Conveyors

Tubular vibratory conveyors are designed for handling and conveying free flowing product and are ideal for a dust free or ATEX environment. A tubular vibratory conveyor will provide a hermetically sealed feed to a downstream conveyor or process.

Laning Vibratory Conveyor

Laning vibratory conveyors are designed to lane or singulate bulk products prior to packaging or other downstream processes.

Spreader Vibratory Conveyor

Spreader vibratory conveyors are designed to provide an even feed of conveyed product to downstream equipment which is typically a freezer or drier. The KMG Spreader vibratory conveyor will gently and efficiently transform a deep bed depth into a single layer of spread product.

These conveyors can incorporate additional functionality including sieving, grading, screening and dewatering. They are ideal for use with cereals and snack products.

Mobile Vibratory Conveyors

Sometimes space constraints can make a mobile vibratory conveyor an attractive option. Where access for maintenance or cleaning is limited, having a mobile vibratory conveyor can be a very effective solution. KMG mobile vibratory conveyors are designed to safely move in and out of their docking position. They are ergonomically designed for ease of use, with manual handling considerations as one of the main design considerations.