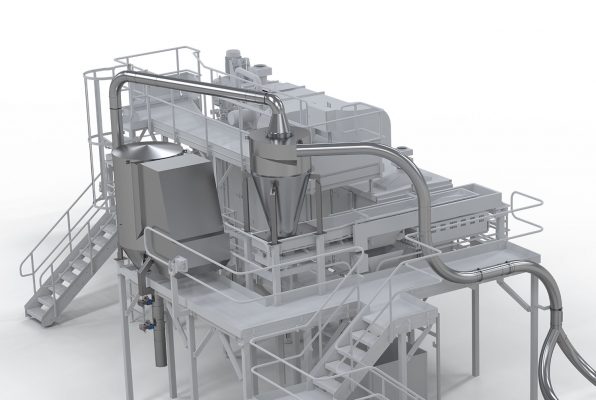

KMG manufacture a range of conveying systems detailed in the following pages for conveying both food and nonfood materials.

Typically, we use vibratory conveyors, flat belt conveyors, flighted belt elevators, modular belts, roller tracks or air conveyors.

The method chosen will be appropriate to the fragility, hygiene, and environment of the process. Also dictating the method are any changes in elevation, direction.

Product can also be distributed to multiple places, sieved, merged or mixed.

Base Products suitable for KMG Vibratory Conveying Systems

Most food materials that can be conveyed on KMG equipment fall into the following categories

- Raw materials, for example potatoes, grains and nuts

- Ingredients, for example pasta, beans and spices.

- Uncooked product, salad leaves, pellets and dried fruit.

- Cooked product, for example, IQF vegetables, nuts and cereals

- Seasoned product, for example, potato chips, tortilla chips

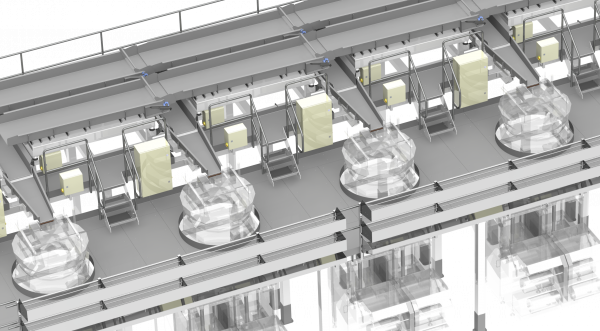

- Packaged products, for example, packets of snacks and cardboard cartons.

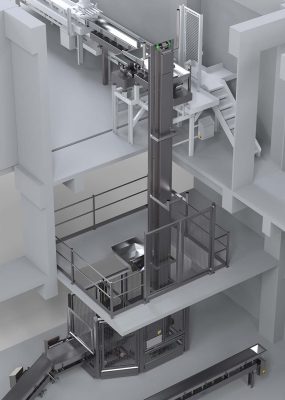

Many KMG Conveying systems will employ one or all the methods above. Critical to the safety and efficiency of the system are the transitions between similar or different machines. Good transitions contain and handle the product gently. At KMG we are experienced in designing the right conveying systems for your product and factory, and our expert sales team have the experience to select the appropriate machine time from our extensive range of different types of conveying systems.

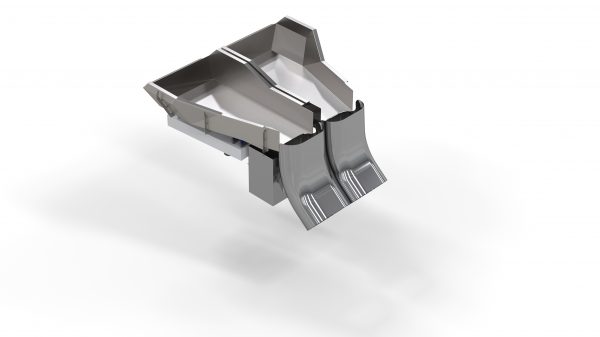

With our experience ,we know that selecting appropriate food contact surface is essential for sanitation and hygiene. As a standard, we would offer stainless 304 surface finish because with our experience we consider this is a cost effective hygienic material which is suitable for a wide range of food products. If your product is particularly acidic, for example fresh fruit or raw meat, or if you use a particularly stringent cleaning product due to your hygiene standards then we would recommend 316 stainless. Where necessary we will use FDA and EU compliant polymers. As you would expect, our material selection optimises the key goals of safety, reliability and value.

We manufacture all our equipment in our state of the art factory. We have made significant investment in welding technology and now have two state of the art laser welding machines. These are capable of a 0.2mm weld which despite being so fine, due to the concentrated heat have excellent penetration with no distortion. Its been a game changer for our design capability, making our equipment even more hygienic and easy to clean. Part of our service includes a complete pre-build in our assembly hall, giving you the opportunity to carry out a pre-finishing pre-delivery inspection. Offering this service gives you the chance to introduce small changes to access or screening before the system is finished.

KMG combine these features with our in house industry leading control and automation to create world class Conveying Systems.